Mejorando la sostenibilidad de los respiradores de emergencia para el Covid-19: un caso de estudio sobre OxyGEN-IP.

![]()

![]()

Revisión | Review

Carlota Armillas-Mateos

MPhil in Engineering for Sustainable Development, University of Cambridge. Centre for Sustainable Development, Engineering

Dept, Trumpington St, Cambridge CB2 1PZ, United Kingdom; e-mail: carlotaarmillas@cantab.net;

ORCID: 0000-0002-9580-3142.

Recibido: 20 de marzo 2021 | Aceptado: 20 de mayo 2021 | Publicado: 29 de junio 2021

DOI: https://doi.org/10.25267/P56-IDJ.2021.i1.4

--------------------------------------------------------------------------------------------------------------------------------------------

Introducción

La pandemia de Covid-19 ha ocasionado una escasez crítica de respiradores disponibles para tratar a pacientes con problemas respiratorios graves en los llamados países de renta alta. Esto ha llevado a medidas de triaje cuya ética puede ser cuestionada, y a un aumento de la mortalidad debido a la falta de equipos (Cohen et al., 2020; Pearce, 2020).

Debido a la limitada capacidad de los fabricantes de respiradores para suministrar suficientes equipos para hacer frente a la pandemia, diversos equipos de todo el mundo han trabajado para proporcionar soluciones de código abierto que puedan fabricarse localmente y ser utilizadas en un hospital convencional de un país de renta alta (Peñarredonda, 2020). Esta urgencia por ofrecer soluciones rápidas para afrontar la emergencia sanitaria y salvar vidas implica que las estrategias de Diseño para la Sostenibilidad Ambiental (DpSA) no sean consideradas como una de las prioridades para el desarrollo de estos nuevos productos. De este modo, se están suministrando respiradores de alta obsolescencia como el VITAL de la NASA, pensado para durar hasta cuatro meses (Greicius, 2020). Además, es posible que algunos respiradores deban desecharse prematuramente, bien para garantizar el cumplimiento de la normativa médica, o bien porque una sola pieza deja de funcionar y el diseño impide su fácil reparación (Protofy, 2020b).

Aunque todavía no se dispone de datos sobre el impacto medioambiental de estos nuevos respiradores, explorar el desafío de cómo se podrían aplicar estrategias de DpSA en el diseño de los respiradores de emergencia para el Covid-19 es interesante por dos razones fundamentales.

En primer lugar, las estrategias de DpSA pueden aportar otros beneficios además de un mejor impacto medioambiental, como la optimización del uso de materias primas escasas, que son más difíciles de conseguir bajo las restricciones del confinamiento y cierres fronterizos (Sherman, 2020), y la reducción de los costes y del tiempo total de fabricación, lo que implica que sería más asequible y rápido fabricar unidades. Un mayor número de dispositivos disponibles y más baratos se traduce en poder atender a más enfermos, especialmente a personas mayores y a pacientes de centros sanitarios desfavorecidos (Cohen et al., 2020; Protofy, 2020b).

En segundo lugar, dado que los Objetivos de Desarrollo Sostenible (ODS) de la ONU dan la misma prioridad a la "acción por el clima", al "consumo y la producción responsables" y a la "buena salud para todos" (Naciones Unidas, 2019), intentar alcanzar uno de los objetivos no debería ir en detrimento de los demás. Los aprendizajes derivados del estudio de este desafío podrían aportar nuevas ideas sobre los compromisos necesarios para alcanzar estos tres ODS simultáneamente. En este sentido, los dispositivos médicos se fabrican para mejorar la salud de las personas, por lo que parece lógico que durante su ciclo de vida se evite la contaminación, que daña la salud pública y el medio ambiente, en la mayor medida posible (Fischer y Riechers, 2019; Proust et al., 2012). Al fin y al cabo, "un buen diseño debe conservar los recursos y minimizar la contaminación a lo largo del ciclo de vida del producto", como afirma Rams (1976).

Por lo tanto, este artículo pretende proporcionar estrategias de DpSA factibles que puedan compartirse con quienes participan en el diseño y la fabricación de uno de estos respiradores, con el objetivo de ayudar a afrontar el Covid-19 de una manera más sostenible. Estas estrategias se proporcionarán tras abordar dos preguntas de investigación: (1) ¿Cuál es el contexto (marco de referencia y redes de contactos propicias) que afecta al diseño y la fabricación del respirador seleccionado?; (2) ¿Qué estrategias de DpSA podrían aplicarse de forma viable para mejorar el rendimiento medioambiental del respirador seleccionado?

Esta investigación se ha llevado a cabo entre el 27 de marzo y el 10 de abril de 2020, en un momento de gran incertidumbre debido al Covid-19 y en un entorno de imperiosa necesidad de respiradores. Para poder responder a las preguntas de investigación anteriores, es necesario elegir un respirador de emergencia para el Covid-19 como caso de estudio. Debido a la incertidumbre existente en el momento de realizar esta investigación, se ha elegido un respirador local español para el análisis, a fin de que la información sea más fácil de acceder y los resultados más fáciles de compartir.

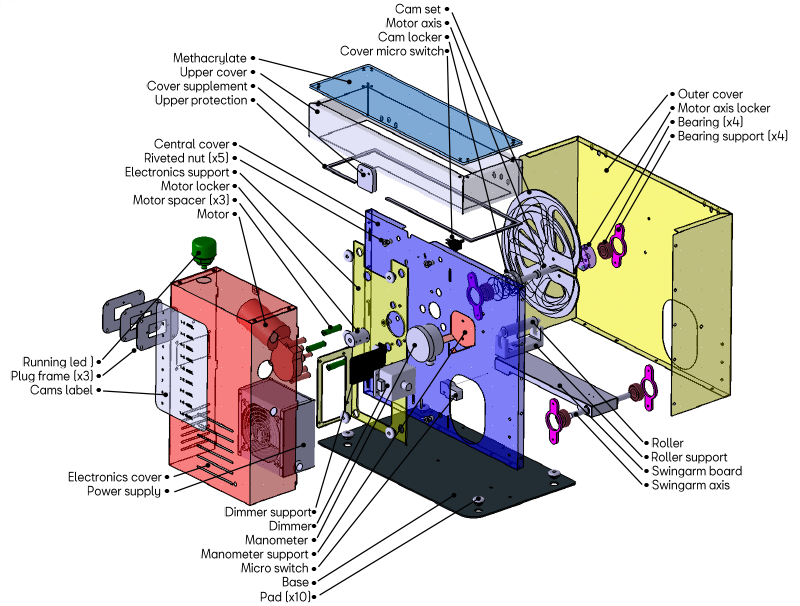

En España, han surgido seis diseños principales de respiradores de emergencia (a fecha de 10 de abril de 2020): Andalucía Respira, Reespirator, Leitat-1, The Open Ventilator, Acute-19, y OxyGEN de Protofy. Este último, el único de código abierto, está siendo descargado por muchos voluntarios en todo el país para fabricar piezas, incluyendo grandes fabricantes como SEAT o Bosch (Mcloughlin, 2020; Pérez, 2020; Vall-Llosada & Marco, 2020) y universidades con capacidad de fabricación. Existen dos versiones del diseño: OxyGEN-M, diseñado para fabricantes; y OxyGEN-IP (Figura 1), diseñado para la producción industrial y que requiere de conocimientos de ingeniería y maquinaria. Sólo OxyGEN-IP cuenta con apoyo legal oficial y está en fase de pruebas (IDNEO Technologies, 2020; Protofy, 2020b; Agencia Española del Medicamento y Productos Sanitarios y Ministerio de Sanidad español, 2020).

Protofy ha habilitado una plataforma en línea donde las diferentes partes interesadas multidisciplinares (hospitales y pacientes (usuarios); investigadores que prueban el dispositivo; fabricantes (empresas y universidades voluntarias); cadenas de suministro (voluntarios); desarrolladores voluntarios interconectados; e instituciones gubernamentales que proporcionan los permisos pertinentes) pueden compartir información (Protofy, 2020a) con el objetivo de salvar el mayor número de vidas posible, en el menor periodo de tiempo. Este enfoque se basa en la ingeniería concurrente, definida como "equipos multidisciplinares que llevan a cabo actividades de procesamiento en paralelo para considerar continuamente todas las restricciones" (Duffy, 1998). Por todo ello, se ha seleccionado OxyGEN-IP como caso de estudio.

OxyGEN-IP proporciona un mecanismo para automatizar un AMBU (respirador/resucitador manual), que se encuentra fácilmente en hospitales y ambulancias. La frecuencia de las tomas de aire, que dependen del paciente, se ajusta mediante la electrónica básica y las cinco palancas disponibles para personalizar el volumen de aire necesario. Esta solución de emergencia está pensada para la producción en serie en chapa metálica y a escala industrial, animando a utilizar piezas de otros productos, como pequeños electrodomésticos (Protofy, 2020a). El producto tiene 177 piezas en total (Protofy, 2020c), clasificadas en la Tabla 1. Los elementos más relevantes se muestran en la Figura 2.

Tabla 1. Piezas de OxyGEN-IP .

|

Tipo |

Chapa metálica |

Mecanizado / impresión 3D |

Electrónica |

Ensamblaje y otros |

TOTAL |

|

Número |

8 (1mm), 3 (3mm) |

10 |

34 |

122 |

177 |

Figura 1. Elementos más relevantes de OxyGEN-IP (Protofy, 2020e).

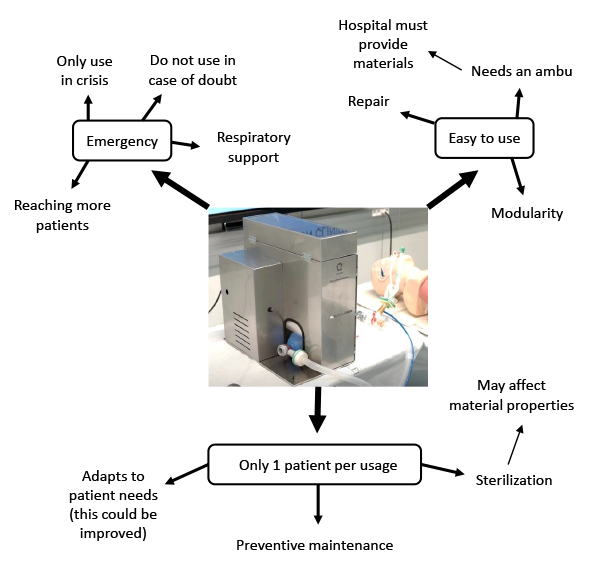

La descripción del producto quedaría incompleta sin información que ayude a entender cómo se va a utilizar este producto: el contexto de uso. El "contexto de uso" puede definirse como "todos los factores que influyen en la experiencia de uso de un producto" (Visser et al., 2005), o la caracterización de "las interacciones entre el producto y el usuario como precursor del desarrollo de una solución de diseño" (Aranda-Jan et al., 2016). Se ha utilizado una herramienta generativa de mapeo contextual definida por Stappers (2003) para resumir la información proporcionada por Protofy sobre el contexto de uso de OxyGEN-IP (Figura 2).

Figura 2. Contexto de uso de Oxygen-IP (elaboración propia). Información obtenida de la guía de usuario de OxyGEN-IP (Protofy, 2020b).

Metodología

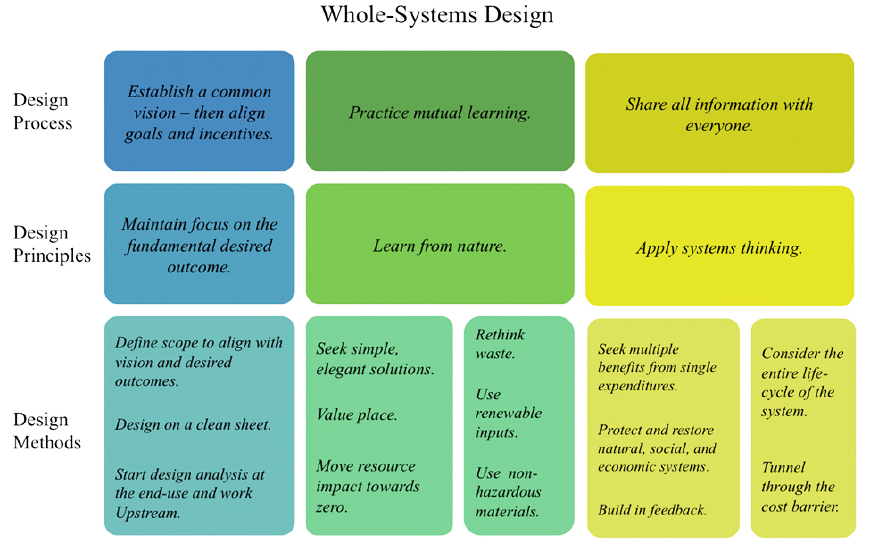

Este estudio de caso se ha examinado desde la perspectiva del Diseño de Sistemas Integrales (DSI) creado por Blizzard y Klotz (2012). Este marco muestra cómo pueden crearse diseños sostenibles mediante el análisis de las interrelaciones entre los diferentes sistemas implicados en el diseño, los problemas y las soluciones, y está pensado para abordar retos difíciles.

Como se ve en la figura 3, el marco del DSI propone tres pilares de diseño. El primer pilar se centra en el proceso de diseño: establecer una visión común para definir los objetivos e incentivos, practicar el aprendizaje mutuo dentro del equipo multidisciplinar y compartir la información de forma transparente con todos (Blizzard y Klotz, 2012). A partir de la literatura disponible, se asume que en Protofy ya siguen estas recomendaciones, por lo que no se profundizará en este pilar.

El segundo pilar presenta dos principios de diseño que pueden ser especialmente relevantes para responder a las preguntas de la investigación. El primer principio es aplicar el pensamiento sistémico, que ayuda a estudiar y comprender el contexto del producto para determinar los elementos contextuales que pueden permitir o limitar las estrategias del DpSA. El segundo principio consiste en mantener el foco en el resultado fundamental deseado, que en este caso significaría que las estrategias del DpSA deberían ayudar a mejorar el acceso a la asistencia sanitaria de los pacientes de Covid-19 que requieren asistencia respiratoria (Blizzard y Klotz, 2012).

Por último, el tercer pilar presenta un conjunto de métodos de eco-diseño. Aunque todos ellos pueden aportar un valor añadido a la hora de abordar la segunda pregunta de investigación, se ha decidido seleccionar uno de estos métodos como guía principal para la toma de decisiones, ya que aplicar todos los métodos con los marcos específicos correspondientes podría llevar demasiado tiempo y en este caso es necesario obtener resultados lo más rápidamente posible.

El método seleccionado es "considerar todo el ciclo de vida del sistema" (Blizzard y Klotz, 2012), porque: (i) Es un método integral que engloba o afecta profundamente a otros, como: repensar los residuos; buscar soluciones sencillas; utilizar insumos renovables; reducir el impacto de los recursos hasta cero; utilizar materiales no peligrosos; proteger y restaurar los sistemas naturales, sociales y económicos; o buscar múltiples beneficios a partir de un solo gasto; (ii) Está alineado con la definición de buen diseño de Dieter Rams presentada en la sección de introducción; (iii) La autora está familiarizada con este método de diseño. Dado que este trabajo pretende ser útil para hacer frente a la actual emergencia sanitaria, el tiempo que se ahorra en el aprendizaje de nuevos métodos implica que los resultados de la investigación pueden compartirse antes.

Figura 3. Marco de Diseño de Sistemas Integrales (DSI) (“Whole-Systems Design” en inglés), adaptado de Blizzard y Klotz (2012).

Tras la discusión anterior, surgen dos fases de investigación (Figura 4). En primer lugar, la selección y aplicación de un marco de diseño para reconocer las relaciones entre los diferentes factores contextuales que afectan al proceso de desarrollo de productos de OxyGEN-IP (por ejemplo: suministro de materiales, mano de obra y máquinas disponibles, requisitos legales, etc.) durante las circunstancias excepcionales de Covid-19, y encontrar los facilitadores y las barreras para aplicar las estrategias DpSA. El resultado de esta etapa responderá a la primera pregunta de investigación. En segundo lugar, seleccionar y utilizar un marco de ecodiseño para identificar las oportunidades de mejora del DpSA a lo largo de todo el ciclo de vida de OxyGEN-IP, y definir las estrategias de diseño que pueden aplicarse de forma viable para mejorar la sostenibilidad de OxyGEN-IP. El resultado de esta etapa responderá a la segunda pregunta de investigación.

Figura 4. Etapas de la investigación (elaboración propia).

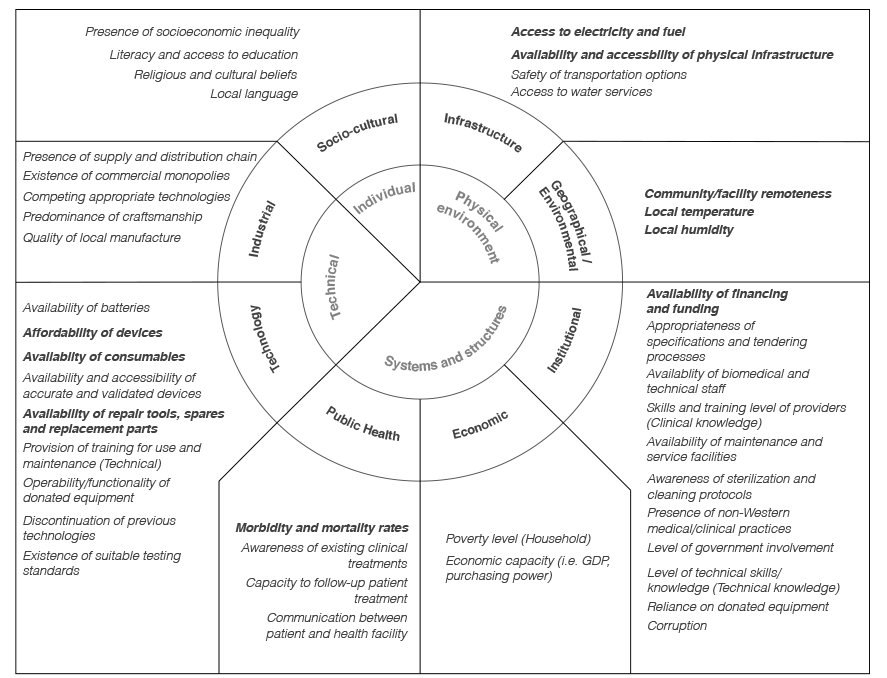

El marco seleccionado para la primera etapa de la investigación es el Marco Contextual Holístico para el Diseño de dispositivos médicos (MCHD) desarrollado por (Aranda-Jan et al., 2016) (Figura 5). El MCHD se centra en entornos de bajos recursos (EBRs), y proporciona un buen resumen de las categorías contextuales holísticas que deben ser exploradas para un diseño eficaz de dispositivos médicos. Aunque la situación en España es diferente a un EBR, las restricciones de confinamiento impuestas, el cierre de fronteras y la interrupción de las cadenas de suministro están limitando seriamente cualquier desarrollo de producto y el acceso a algunos recursos. Por lo tanto, si y sólo si se aplica dentro de los límites del sistema de restricciones de emergencia debidas al Covid-19, este marco puede ser un buen enfoque para no descartar ningún factor relevante que pueda afectar al diseño de OxyGEN-IP durante la emergencia sanitaria.

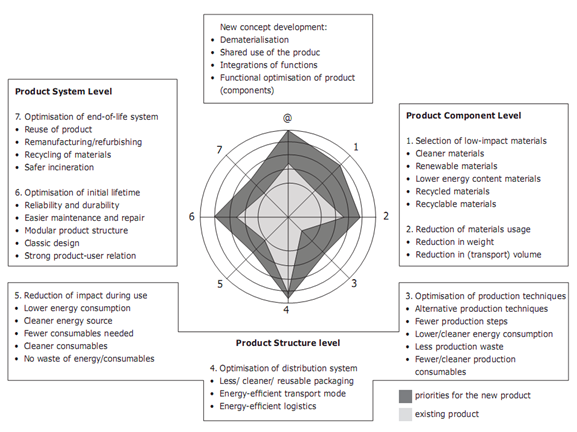

La herramienta de diseño seleccionada para la segunda fase de la investigación se basa en la Rueda Estratégica de Ecodiseño (REE) de Brezet y Hemel (1997) (Figura 6). Esta herramienta visual ayuda a detectar áreas de mejora ambiental para seleccionar estrategias de ecodiseño (Olieman, 2011b). La REE se recomienda para presentar y seleccionar estrategias de diseño de productos cuando se dispone de una idea de producto, en las primeras fases del desarrollo y del análisis temprano del problema (Olieman, 2011b). Por eso, se considera adecuado en este caso.

Figura 5. Factores contextuales del MCHD (Aranda-Jan et al., 2016)

Figure 6. The Eco-design strategy wheel (Brezet & Hemel, 1997)

Normalmente, el punto de partida es el resultado de una matriz MET y una lista de verificación de ecodiseño (Olieman, 2011b). La matriz MET se utiliza para analizar el ciclo de los materiales, el uso de la energía y las emisiones tóxicas durante la obtención y el consumo de la materia prima, la fabricación, la distribución, el uso y el final de la vida útil (Olieman, 2010). Sin embargo, este análisis no puede incluirse en esta investigación debido a la falta de datos disponibles, reconociendo que es una limitación para elaborar cualquier estrategia de mejora de la sostenibilidad. En consecuencia, no se va a utilizar la MET. Por otro lado, la lista de verificación de ecodiseño proporciona un conjunto de preguntas relacionadas con cada etapa de la rueda de ecodiseño, y ayuda a poner de manifiesto los cuellos de botella medioambientales en las distintas etapas del ciclo de vida del producto (Olieman, 2011a). Esta herramienta se ha utilizado para caracterizar el estado actual e identificar las áreas de actuación adecuadas, añadiendo preguntas adicionales cuando se ha considerado pertinente para identificar otros impulsores o barreras.

La REE se va a aplicar según el siguiente procedimiento, basado en las recomendaciones de (Olieman, 2011b): (1) Definición de OxyGEN-IP (la definición del producto proporcionada en la introducción se completará con la información contextual obtenida gracias al MCHD); (2) Puntuación de OxyGEN-IP en cada dimensión de la REE, utilizando la información de la lista de verificación de ecodiseño; (3) Elaboración de estrategias de DpSA para cada dimensión en la que la mejora es factible y necesaria (las peores puntuaciones se examinarán con más detenimiento).

Por último, se evaluará la viabilidad de las estrategias de DpSA para la mejora del producto teniendo en cuenta toda la información contextual recopilada gracias al MCHD. El resultado de este análisis consistirá en un conjunto de estrategias recomendadas.

Resultados

La información sobre el contexto holístico de OxyGEN-IP, obtenida como resultado de la aplicación del MCHD dentro de los límites del sistema de restricciones por el Covid-19, se resume en la Tabla 2. El análisis holístico del contexto, junto con la información recopilada gracias a la lista de comprobación del ecodiseño, ha ayudado a responder a todas las preguntas de la REE. Se han dado puntuaciones relativas al rendimiento medioambiental actual en cada dimensión de la rueda, para detectar visualmente las oportunidades de mejora (Figura 7). Una puntuación más baja significa que se estima que hay una mayor necesidad de mejora. La dimensión 4 se ha dejado fuera de esta evaluación debido a la falta de información suficiente para realizar una valoración.

Tabla 2. MCHD de OxyGEN-IP dentro de los límites de las restricciones por el Covid-19 relevantes para el diseño de respiradores de emergencia, basado en Aranda-Jan, Jagtap y Moultrie (2016).

|

Contexto de sistemas e infraestructuras |

|

|

Salud Pública |

Pandemia de Covid-19 en España: segundo país más afectado de Europa (en términos de total de casos confirmados y número de muertos), a partir del 10 de abril de 2020 (OMS, 2020).

Sistema sanitario y trabajadores desbordados en algunas regiones. Algunos pacientes no están siendo tratados debido a la escasez de respiradores mecánicos (Guerrero, 2020).

Los ciudadanos están en situación de confinamiento hasta finales de abril, a partir del 10 de abril de 2020. |

|

Economía |

Los gobiernos regionales y nacionales están haciendo esfuerzos para conseguir más fondos para la compra de materiales. Los expertos estiman un aumento del 30% de la deuda pública debido al brote de la pandemia, lo que significa que la deuda alcanzaría aproximadamente el 130% sobre el PIB (Faes, 2020).

Se ha pedido a todos los trabajadores no esenciales que hagan cuarentena en casa.

Muchas personas se están quedando sin trabajo, o están en situación de ERTE. |

|

Institucional |

La gestión gubernamental tiene tres niveles: local, regional y nacional. Ha habido problemas a la hora de transferir las competencias de las regiones al Ministerio de Sanidad nacional, pero la coordinación entre regiones está siendo más fluida. Otros ministerios están adoptando medidas que debería tomar el Ministerio de Sanidad (García de Blas, 2020).

La sanidad está desbordada y pide ayuda. Hay muchos profesionales bien formados y con conocimientos para desarrollar y utilizar el producto. |

|

Contexto físico-ambiental |

|

|

Infraestructura |

Infraestructura típica de país de renta alta |

|

Geográfico-ambiental |

Los dispositivos médicos deben ser desechados siguiendo una normativa específica. |

|

Contexto individual |

|

|

Socio-cultural |

Alta solidaridad. Muchos voluntarios han mostrado interés en colaborar con el proyecto, como SEAT, universidades nacionales, comunidades locales de makers conectadas por las redes sociales y particulares. |

|

Contexto técnico |

|

|

Tecnología |

Asequibilidad de los dispositivos, consumibles, dispositivos accesibles, herramientas de reparación y piezas de repuesto disponibles y normas internacionales en vigor.

Existencia de normas de ensayo adecuadas. Los productos sanitarios deben estar certificados por la Agencia Española de Medicamentos y Productos Sanitarios. |

|

Industrial |

Capacidad de fabricación de alta calidad, cadenas de suministro limitadas, monopolios comerciales. Muchas empresas se encuentran actualmente bajo la paralización legal por el Covid-19. |

Figura 7. Evaluación del estado actual de OxyGEN-IP (por el autor), basada en la rueda de estrategia de ecodiseño de Brezet y Van Hemel (1997).

Tras este ejercicio, se ha llegado a la conclusión de que las estrategias potencialmente viables para mejorar la sostenibilidad medioambiental del OxyGEN-IP pueden estar relacionadas con las siguientes dimensiones de la REE: (a) Optimizar la función (dimensión 0): Evitar piezas redundantes, teniendo en cuenta que el diseño actual tiene 177 piezas, y mejorar la compatibilidad con los dispositivos requeridos por el hospital. (b) Elegir materiales de bajo impacto ambiental (dimensión 1), y disminuir la cantidad de material utilizado (dimensión 2). Las mejoras en este ámbito pueden suponer un reto debido a la desaceleración de la red industrial y de los proveedores. Debe considerarse el uso de componentes electrónicos funcionales de dispositivos no operativos que estén disponibles. (c) Optimizar las técnicas de producción para ahorrar tiempo y aumentar la eficiencia (dimensión 3). No se pueden cambiar los procesos de fabricación disponibles, pero sí el montaje. También pueden explorarse las técnicas de fabricación Lean. (d) Evaluar si se pueden utilizar consumibles más limpios (dimensión 5), con especial atención a las bolsas desechables AMBU; (e) Alargar la duración de la vida del producto (dimensión 6), con especial atención al mantenimiento y la esterilización. (f) Optimización del final de la vida útil (dimensión 7). En España, la eliminación de los productos sanitarios debe seguir una normativa estricta, por lo que el reto podría ser fomentar de forma segura la reutilización de todo el producto (o sólo de algunas partes) y su desmantelamiento.

A continuación, se ha utilizado la información de la lista de verificación de ecodiseño y del MCHD, junto con otras herramientas, enfoques y principios diferentes, para analizar, discutir y recomendar estrategias de mejora finales para cada una de las dimensiones o para varias de ellas (ya que algunas de las estrategias mencionadas están interrelacionadas). Después, se ofrece una discusión sobre los desafíos para la implementación de las estrategias sugeridas.

El marco de la REE aconseja que solo se incluyan estrategias de ecodiseño a corto plazo en la lista de requisitos para el rediseño (Olieman, 2011b). En este caso, dada la situación de emergencia, todas las acciones que se realicen deben aplicarse a corto plazo. Esto no significa que se descarten las acciones a largo plazo que puedan surgir; simplemente no se les da prioridad.

Reducir el número de piezas

El principal problema de OxyGEN-IP es su elevado número de piezas: 177. Esto conlleva largos tiempos de montaje y desmontaje, que podrían aprovecharse para fabricar más unidades. Además, desechar tantas piezas no es improbable: Los desarrolladores subrayan que este dispositivo de emergencia debería ser sustituido en caso de duda sobre su correcto funcionamiento, lo que se traduciría en un desperdicio evitable de materiales valiosos.

La mayoría de los componentes se utilizan para el ensamblaje de las piezas (122), por lo que es evidente que este proceso provoca un cuello de botella en términos de sostenibilidad. Esta cuestión debería abordarse con una estrategia de "diseño para el montaje", consistente en reducir el número de piezas de un producto y hacer que el proceso de montaje sea más fácil y rápido (tanto para los procesos manuales como para los automáticos) (Kent, 2016) para ahorrar costes, tiempo, recursos y residuos (Blizzard y Klotz, 2012).

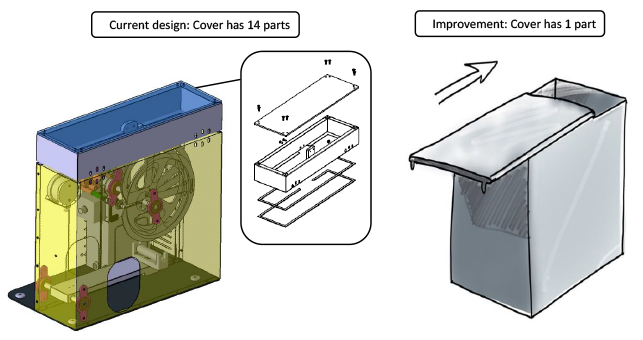

Cuestionar la función y el diseño de los componentes, utilizando herramientas como la jerarquía de funciones, puede ser útil para abordar este proceso de simplificación (Morgan, 2020). Por ejemplo, la tapa de la caja de mecanismos está compuesta por 14 piezas (véase la figura 8). Tiene la funcionalidad de proteger el mecanismo mientras está cerrado y facilitar el acceso a las palancas de cambio o a los componentes rotos si se abre (gracias a su bisagra). No es necesario un cierre hermético. Tras un análisis de jerarquía de funciones, resulta que esas 14 piezas podrían simplificarse en una sola pieza deslizante, igualmente funcional y más fácil de fabricar. Se recomienda que el equipo de diseño practique este ejercicio con otros componentes del producto para analizar si es posible una mayor simplificación.

También debería examinarse la funcionalidad del sistema de palanca, ya que otros investigadores han encontrado formas más sencillas de presionar la bolsa AMBU (Peñarredonda, 2020), lo que se traduce en un menor número de piezas y en evitar la extracción de la palanca (cualquier palanca extraída del interior debe ser esterilizada, lo que hace que los hospitales pierdan tiempo y recursos en la esterilización).

Figura 8.Boceto original de la propuesta de reducción parcial (por el autor), basado en (Protofy, 2020d, 2020c, 2020e).

Por último, el consumible más destacado que requiere OxyGEN-IP es el AMBU, que está fabricada en plástico y debe desecharse después de tratar a un paciente (AMBU Australia, 2020). La evaluación de la funcionalidad del AMBU, con el objetivo final de desarrollar un dispositivo reutilizable de forma segura, podría abrir una línea de investigación paralela a más largo plazo que quedaría fuera de los límites del sistema de esta investigación.

Diseño para la compatibilidad y adaptabilidad

Hay que tener en cuenta que OxyGEN-IP es un producto de emergencia que podría dejar de ser necesario en los hospitales españoles tras la crisis del coronavirus. Por lo tanto, hay varias opciones en torno a su fin de vida: 1) eliminación del dispositivo médico, generando contaminación en caso de que se considere que no es seguro reciclarlo (como el producto está en fase de pruebas, esto es todavía una incógnita (IDNEO Technologies, 2020)); 2) donarlo a instalaciones médicas que lo necesiten si el dispositivo sigue funcionando (podría tratarse de otro país de renta alta o baja que necesite dispositivos de ventilación mecánica de bajo coste), para seguir salvando vidas.

Como establece la jerarquía de gestión de materiales, es preferible reducir que reutilizar o reciclar (Blizzard y Klotz, 2012; Linton y Jayaraman, 2005), por lo que esta segunda opción parece más sostenible. Pero hay un obstáculo: OxyGEN-IP solo es compatible con dos tipos diferentes de resucitadores manuales AMBU, y debe estar conectado tanto al circuito de oxígeno del hospital como a una fuente fiable de electricidad según la normativa europea, lo que limita su uso a los centros sanitarios con esa disponibilidad.

Dos estrategias de diseño de productos circulares pueden ser útiles para alargar y optimizar la vida útil del producto: el "diseño para la compatibilidad", una estrategia de diseño de productos circulares que consiste en estandarizar los productos en la medida de lo posible para que se adapten a una gama más amplia de otras piezas del producto (Bocken et al., 2016); y el "diseño para la adaptabilidad", que busca modificaciones que permitan un mayor uso (Morgan, 2020).

De este modo, OxyGEN-IP debería modificarse de manera que pueda utilizarse con más tipos de reanimadores manuales, en relación con los diferentes equipos disponibles por hospital (Peñarredonda, 2020), y conectarse a una botella de oxígeno en caso de que el tratamiento sea necesario en un centro sanitario sin instalación de oxígeno. Este cambio puede ser habilitado mediante un diseño modular, que permite modificar los componentes electrónicos y eléctricos, en caso de que sea necesario ajustar la compatibilidad eléctrica a un contexto diferente.

Estrategias de materiales

Las piezas principales de la carcasa están pensadas para ser fabricadas en acero inoxidable, nylon, metacrilato, acero o silicona (Protofy, 2020b), mediante procesos de chapa metálica, corte por láser y mecanizado. Las organizaciones voluntarias también han ofrecido sus máquinas de fabricación aditiva, a pesar de que estos procesos y materiales no están incluidos en el manual de OxyGEN-IP ni en las pruebas.

La selección de materiales no sería un reto en condiciones normales, pero sí lo es cuando las cadenas de suministro están paralizadas, lo que lleva a las empresas a utilizar cualquier material que tengan en stock o que puedan conseguir con relativa facilidad. Así, las limitaciones del contexto dificultan el libre acceso a materiales de bajo impacto. Por ello, los voluntarios de una región o proyecto deberían compartir un inventario de los recursos que podrían poner a disposición en una plataforma compartida basada en la nube para ayudar a reasignar, adaptar o reutilizar los recursos locales (también los electrónicos), tal y como aconsejan los principios de diseño sostenible de Blizzard y Klotz (2012) mencionados al principio de la sección 2. Se recomienda utilizar, siempre que sea posible, materiales limpios, de bajo consumo energético, reciclados o reciclables (Olieman, 2011a) que estén certificados para su uso en el ámbito sanitario; y, a continuación, aplicar estrategias de diseño para reducir el peso del material, con el objetivo de maximizar el número de piezas que podrían fabricarse con los limitados recursos disponibles.

Otra restricción viene dada por la función: el material elegido debe soportar métodos de desinfección como los químicos o los UV; por no añadir la larga lista de estrictos requisitos que los dispositivos médicos ordinarios deben cumplir durante su vida útil (Peñarredonda, 2020) y su descarte.

La impresión 3D puede ser interesante para reducir el peso de los materiales utilizados y fabricar formas complejas (Plocher & Panesar, 2019). Sin embargo, en este caso, la impresión 3D se recomienda para artículos desechables en lugar de piezas reutilizables (como los mecanismos), ya que la porosidad del plástico puede retener el virus, y la esterilización térmica puede comprometer la estabilidad estructural del material (Maróti et al., 2020). Las investigaciones han mostrado algunos resultados positivos respecto a la esterilización con H2O2 (Oth et al., 2019), que puede provocar ligeros cambios de masa o dimensionales y deformaciones, dependiendo del material (no significativos en PLA o PCL, por ejemplo), pero que no afectan al uso si y solo si son previstos por los diseñadores (Sosnowski & Morrison, 2017). Sin embargo, algunos autores siguen siendo reticentes a la hora de recomendar esta tecnología para la fabricación de respiradores, dados los posibles problemas de seguridad (Aydin et al., 2021; S. Singh et al., 2020; S. N. Singh et al., 2021).

Optimización de la producción

A pesar de que la producción está muy limitada, ya que las empresas voluntarias no pueden modificar sus recursos, puede optimizarse simplificando el montaje (como se explica en el apartado 2.2.1) y adoptando un enfoque de Lean Manufacturing. La fabricación Lean tiene como objetivo eliminar continuamente los residuos del proceso de fabricación, entendiendo por residuo cualquier cosa no deseada, como los tiempos muertos o la contaminación. Una de las herramientas Lean está relacionada con el solapamiento de las fases de producción cuando es posible para reducir el tiempo de comercialización (Orji y Liu, 2020).

Henao, Sarache y Gómez (2019) muestran cómo las organizaciones sostenibles y resilientes utilizan ampliamente las técnicas Lean, sobre todo como complemento de la cadena de suministro, integración tecnológica y metodologías ágiles. El hecho de que el proceso de diseño de OxyGEN-IP siga un enfoque de ingeniería concurrente para su desarrollo es otro facilitador.

Hasta ahora, muchos equipos voluntarios han trabajado de forma independiente, fabricando todas las piezas que podían de forma secuencial. En el desarrollo de otros productos de emergencia de Covid-19, la falta de coordinación se tradujo en una sobreproducción de dispositivos (Temple, 2020). Por ello, los grupos de voluntarios que deseen fabricar el respirador OxyGEN-IP deben coordinarse con otros grupos locales para solapar las fases de fabricación en función de la capacidad de cada uno. Se espera que la suma de esfuerzos coordinados se traduzca en respiradores de emergencia entregados más rápidamente, porque las piezas necesarias para fabricar una unidad se obtendrían antes. Además, se espera que este enfoque evite el desperdicio innecesario debido a la sobreproducción.

Diseño para la durabilidad del producto

A pesar de que el desecho de los productos sanitarios está regulada, por lo que no puede incluirse en el ámbito de esta investigación, se pueden revisar los principios para extender la durabilidad del producto. En este caso, la durabilidad está relacionada principalmente con el mantenimiento del producto, la resistencia a la esterilización y el desgaste (Pearce, 2020; Protofy, 2020b).

Una mejora en esta línea podría ser la modificación del sistema de levas utilizado para ajustar el volumen y la frecuencia de insuflación, ya que el actual da lugar a problemas de mantenimiento: dos piezas (el muelle y el rodillo) son susceptibles de sufrir desgaste con la distribución actual, necesitando ser sustituidas varias veces durante la vida del producto (Protofy, 2020b). Una redistribución de los componentes o un tratamiento superficial podrían evitar este problema.

En cuanto a la sustitución de los componentes que fallan, la investigación de Linton y Jayaraman (2005) muestra que la reparación es una opción económicamente atractiva para la extensión de la vida útil de los productos electrónicos, como en el caso de OxyGEN-IP. Esto tiene sentido: Protofy recomienda reutilizar el motor y la electrónica, y fomenta la reparación del producto mediante un diseño modular.

La reparación está vinculada a la estrategia de producto circular "diseñar para facilitar el mantenimiento y la reparación". Esta estrategia, utilizada por el fabricante de móviles Fairphone para permitir a los usuarios arreglar sus propios teléfonos, se basa en una inspección sin esfuerzo de los posibles fallos y la sustitución de las piezas rotas (Fairphone, 2020). Ambas pueden verse reforzadas por otra estrategia de producto circular denominada "diseño para el desensamblaje y el reensamblaje" (relacionada con la estrategia de diseño para el ensamblaje descrita en la sección 2.2.1), que facilita y agiliza la separación de los componentes a la hora de reparar o desechar el producto, así como el reensamblaje del conjunto (Bocken et al., 2016).

Discusión

El principal reto para aplicar las estrategias de diseño propuestas es la incertidumbre que reina durante la crisis de salud pública por el Covid-19. La novedad del virus hace que cada día se generen nuevos hallazgos y datos, y que los responsables políticos puedan permitir o prohibir inesperadamente algunos productos dependiendo de las circunstancias, como ocurrió con las pantallas faciales impresas en 3D que fueron rechazadas en Madrid tres días después de su aprobación por no estar certificadas (Peinado, 2020). El propio OxyGEN-IP también está sometido a una gran incertidumbre, porque durante la realización de esta investigación todavía está en fase de pruebas técnicas.

El enfoque de ingeniería concurrente adoptado por proyectos de código abierto como OxyGEN-IP y otros que pretenden ayudar a hacer frente a la pandemia de Covid-19 ha sido criticado, alegando que una producción abrumadora y un trabajo en equipo disperso pueden conducir a resultados ineficientes que no son útiles para salvar vidas (Temple, 2020), y que sólo generan desperdicios. Además, algunos monopolios de dispositivos médicos propietarios de patentes han iniciado acciones legales contra algunos grupos de código abierto, como ha ocurrido en Italia (Pearce, 2020). Este problema podría haberse evitado si los grupos hubieran realizado un análisis holístico del contexto (como en este trabajo) para identificar estos riesgos potenciales y tratar de encontrar soluciones, lo que reafirma la importancia del análisis contextual de la sección 2.1.

Algunas estrategias de mejora, como la reducción del número de piezas o la durabilidad del producto, son más fáciles de aplicar, ya que sólo dependen del equipo de desarrollo y ese trabajo puede hacerse desde casa. Sin embargo, las limitaciones de Covid-19 son una seria amenaza para aplicar una estrategia de materiales más sostenible, ya que no es fácil adquirir materiales de bajo impacto que cumplan con la normativa de productos sanitarios en un contexto de economía paralizada, deudas crecientes y empresas que entran en quiebra (Faes, 2020). Estas restricciones también pueden impedir el intercambio de componentes o causar el cierre de centros productivos, lo que complica la red de producción optimizada de Lean. También hay que tener en cuenta que, en caso de que los proveedores, fabricantes o distribuidores no obtengan el permiso legal para actuar, todo el proyecto podría quedar en pausa hasta nuevo aviso.

La estrategia de diseño para la compatibilidad pretende crear un producto universal dentro de una alta competencia en el mercado (es decir, compatible con multitud de variedades del mismo dispositivo), por lo que podría no ser factible a corto plazo. Por ejemplo, hay más de dieciséis empresas que fabrican sus propios modelos de AMBU (Grand View Research, 2019). Por lo tanto, podría ser más fructífero empezar centrando los esfuerzos en un contexto objetivo restringido.

Por último, existe otra preocupación relacionada con la durabilidad del producto. La investigación de Pearce (2020) muestra que, si no se mantienen en un entorno estéril, los dispositivos podrían contaminarse biológicamente, necesitando un lavado o un baño químico. El personal sanitario en España informa de que la esterilización de los productos de emergencia de plástico reduce drásticamente su vida útil (Bañuelos, 2020), por lo que algo similar podría ocurrir con OxyGEN-IP.

La metodología de la investigación también está sujeta a algunas limitaciones. Hasta el 10 de abril de 2020, día en que se terminó esta investigación, las búsquedas en Science Direct y Scopus con las palabras clave "sustainable OR sustainability" AND "design" AND (Covid-19 OR coronavirus OR Covid OR Ventilator) proporcionaron 0 resultados relevantes para los objetivos de esta investigación. Esto significa que, mientras se realizaba esta investigación, no existía bibliografía sobre este tema específico y que, en consecuencia, se trataba de una investigación novedosa. Esta novedad significa que era más difícil obtener datos para ayudar a los responsables de la toma de decisiones, ya que no había referencias sobre lo que podría ir mal o bien. Además, no se dispone de mucha información detallada sobre el diseño de otros respiradores de emergencia, por lo que las comparaciones con otros diseños, beneficiosas para aportar distintas percepciones e ideas, serán superficiales. También, la situación de Covid-19 se volvió crítica en España sólo dos semanas antes de la realización de esta investigación, está cambiando rápidamente y se hacen nuevos descubrimientos a diario, algunos de ellos contradictorios. Por ejemplo, muchos respiradores de código abierto que fueron alabados en marzo están siendo criticados ahora por ser inseguros (McManus, 2020). Esto significa que, tal vez, algunas de las estrategias propuestas como resultado de esta investigación no se consideren viables en un futuro.

Inevitablemente, la selección de los marcos o herramientas de diseño y la interpretación de los resultados serán subjetivos según el criterio, la perspectiva y la experiencia de la autora como ingeniera de diseño. El hecho de que este trabajo haya tenido que realizarse de forma individual, incluso con el objetivo final de compartir los resultados, puede contradecir el principio del DMS de aprendizaje mutuo. Para mitigar esto, sería interesante pedir la opinión de un grupo de diseñadores (tanto internos como externos al diseño de OxyGEN-IP), para reducir la subjetividad, y verificar o descartar algunas de las suposiciones hechas (como la suposición hecha sobre que Protofy promueve efectivamente el aprendizaje mutuo y la comunicación interna).

Conclusiones

Esta innovadora investigación ha consistido en encontrar un equilibrio entre la sostenibilidad medioambiental y la mejora del acceso a la asistencia sanitaria. Adoptando una perspectiva de Diseño de Sistemas Integrales (Blizzard & Klotz, 2012), esta investigación ha aplicado el Marco Contextual Holístico para el Diseño de dispositivos médicos (Aranda-Jan et al., 2016), la Rueda de Estrategias de Ecodiseño (Brezet & Hemel, 1997) y algunas otras herramientas y principios para recomendar estrategias de diseño y fabricación que ayuden a mejorar la sostenibilidad ambiental del respirador mecánico de emergencia OxyGEN-IP desarrollado por Protofy, con el objetivo de ayudar a abordar el problema de salud pública ocasionado por la pandemia de Covid-19 de una manera más sostenible.

Las estrategias de diseño y fabricación recomendadas pueden agruparse en cuatro categorías: diseño para el montaje, vida útil del producto, uso de materiales y enfoque de fabricación Lean.

Se recomienda un enfoque de diseño para el ensamblaje con el fin de reducir drásticamente el elevado número de piezas de ensamblaje (122 en total), lo que también puede suponer una reducción de costes y de tiempo.

A continuación, se recomienda ampliar la vida útil del producto mediante (a) modificar el diseño para que sea compatible con más tipos de AMBUs o botellas de oxígeno, aumentando así su accesibilidad; (b) mejorar el diseño modular con técnicas de desmontaje, de forma que se pueda acceder fácilmente a los componentes electrónicos y eléctricos para repararlos y modificarlos de forma efectiva; (c) redistribuir los componentes del sistema de levas, o aplicar tratamientos superficiales, para reducir el desgaste que sufren estos componentes.

En cuanto al uso de materiales, se recomienda crear una plataforma basada en la nube en la que grupos de voluntarios cercanos puedan compartir información sobre los recursos que pueden ofrecer, y así ayudar a reasignar, adaptar o reutilizar los recursos locales. Además, se recomienda seleccionar materiales que puedan soportar métodos de desinfección (químicos o UV), y sólo imprimir en 3D si se garantiza que esas piezas pueden ser desinfectadas con seguridad sin perder su funcionalidad.

Por último, se ha recomendado adoptar una perspectiva de fabricación lean para reducir el tiempo total de producción y los residuos innecesarios debidos a la sobreproducción. Esto podría conseguirse coordinando y planificando las tareas interrelacionadas de los voluntarios locales.

A pesar de que se necesitan más esfuerzos para superar los retos de aplicación identificados durante la definición de las estrategias, se espera que las recomendaciones anteriores puedan ponerse en práctica a corto plazo para obtener beneficios en términos de un mejor impacto medioambiental, menores costes y tiempo total de fabricación.

Los siguientes pasos inmediatos serían compartir estos resultados con el equipo de Protofy u otros voluntarios que fabrican OxyGEN-IP para evaluar la viabilidad de las estrategias propuestas en el entorno real, materializarlas en cambios en el diseño del producto. Esto permitiría medir y validar el impacto medioambiental de los cambios propuestos. Otras líneas de trabajo podrían centrarse en mejorar la sostenibilidad de otros productos diseñados para hacer frente a la emergencia de Covid-19.

Sería interesante seguir explorando el problema desde la perspectiva de la sostenibilidad social. Esta dimensión de la sostenibilidad ha quedado fuera del ámbito de esta investigación, pero podría aportar nuevos beneficios que, de otro modo, quedarían sin explorar. Una herramienta que podría utilizarse para dicho análisis es el marco de diseño para la sostenibilidad social de Corsini y Moultrie (2019). También merecería la pena analizar este caso de estudio con otras herramientas de sostenibilidad ambiental, y luego comparar los resultados.

Por último, esta investigación ha puesto de manifiesto la inexistencia de marcos o guías que ayuden a diseñar y fabricar dispositivos médicos de emergencia sostenibles. Sería especialmente interesante explorar cómo las enseñanzas de este caso de estudio podrían aplicarse al diseño de dispositivos médicos sostenibles para entornos de bajos recursos, donde el acceso limitado a la asistencia sanitaria es un reto constante no sólo en tiempos de Covid-19. Esta futura investigación podría aportar beneficios al diseño humanitario y ayudar a alcanzar el objetivo de desarrollo sostenible "atención sanitaria para todos", mientras se trabaja en pro del "consumo y la producción responsables" y la "acción climática".

Referencias

AMBU Australia. (2020). Ambu—Devices that save lives & improve patient care. https://www.ambu.com/

Aranda-Jan, C. B., Jagtap, S., & Moultrie, J. (2016). Towards A Framework for Holistic Contextual Design for Low-Resource Settings. 10(3), 21.

Aydin, A., Demirtas, Z., Ok, M., Erkus, H., Cebi, G., Uysal, E., Gunduz, O., & Ustundag, C. B. (2021). 3D printing in the battle against COVID-19. Emergent Materials, 4(1), 363–386. https://doi.org/10.1007/s42247-021-00164-y

Bañuelos, J. (2020, March 30). Ayuso se ve obligada a suspender el uso de protecciones impresas en 3D por no tener el visto bueno de Sanidad. Cadena SER. https://cadenaser.com/emisora/2020/03/30/radio_madrid/1585522735_465105.html

Blizzard, J., & Klotz, L. (2012). A framework for sustainable whole systems design. Design Studies, 33, 456–479. https://doi.org/10.1016/j.destud.2012.03.001

Bocken, N. M. P., de Pauw, I., Bakker, C., & van der Grinten, B. (2016). Product design and business model strategies for a circular economy. Journal of Industrial and Production Engineering, 33(5), 308–320. https://doi.org/10.1080/21681015.2016.1172124

Brezet, H., & Hemel, C. van. (1997). Ecodesign: A Promising Approach to Sustainable Production and Consumption. United Nations Environment Programme, Industry and Environment, Cleaner Production.

Cohen, I. G., Crespo, A. M., & White, D. B. (2020). Potential Legal Liability for Withdrawing or Withholding Ventilators During COVID-19: Assessing the Risks and Identifying Needed Reforms. JAMA, 323(19), 1901. https://doi.org/10.1001/jama.2020.5442

Corsini, L., & Moultrie, J. (2019). Design for Social Sustainability: Using Digital Fabrication in the Humanitarian and Development Sector. Sustainability, 11(13), 3562. https://doi.org/10.3390/su11133562

Duffy, A. H. B. (Ed.). (1998). The Design Productivity Debate. Springer-Verlag. https://doi.org/10.1007/978-1-4471-1538-0

Faes, I. (2020, April 4). La crisis del coronavirus disparará la deuda hasta el 130% y aboca a España a un rescate. El Economista. https://www.eleconomista.es/economia/noticias/10462410/04/20/La-crisis-del-coronavirus-disparara-la-deuda-hasta-el-130-y-aboca-a-Espana-a-un-rescate.html

Fairphone. (2020). Fairphone | The phone that cares for people and planet. https://www.fairphone.com/en/

Fischer, J., & Riechers, M. (2019). A leverage points perspective on sustainability. People and Nature, 1(1), 115–120. https://doi.org/10.1002/pan3.13

García de Blas, E. (2020, April 5). La crisis tensiona el Estado autonómico. El País. https://elpais.com/espana/2020-04-05/la-crisis-tensiona-el-estado-autonomico.html

Grand View Research. (2019). Manual Resuscitators Market Size | Industry Analysis Report, 2019-2025 (Industry Analysis Report GVR-1-68038-012-5; p. 100).

Greicius, T. (2020, April 23). NASA Develops COVID-19 Prototype Ventilator in 37 Days [NASA Jet Propulsion Laboratory]. NASA. http://www.nasa.gov/feature/jpl/nasa-develops-covid-19-prototype-ventilator-in-37-days

Guerrero, A. (2020, April 1). Coronavirus: ‘Hemos dejado de intubar a enfermos por su edad porque no hay respiradores para todos’. RTVE.es. https://www.rtve.es/noticias/20200401/hemos-dejado-intubar-enfermos-su-edad-porque-no-hay-respiradores-para-todos/2011083.shtml

Henao, R., Sarache, W., & Gómez, I. (2019). Lean manufacturing and sustainable performance: Trends and future challenges. Journal of Cleaner Production, 208, 99–116. https://doi.org/10.1016/j.jclepro.2018.10.116

IDNEO Technologies. (2020). Compliance Laboratory—EMC Test Report accredited by ENAC according to EN ISO/IEC 17025 (No. BE2020063).

Kent, R. (2016). Chapter 8—Design quality management. In R. Kent (Ed.), Quality Management in Plastics Processing (pp. 227–262). Elsevier. https://doi.org/10.1016/B978-0-08-102082-1.50008-3

Linton, J. D., & Jayaraman, V. (2005). A framework for identifying differences and similarities in the managerial competencies associated with different modes of product life extension. International Journal of Production Research, 43(9), 1807–1829. https://doi.org/10.1080/13528160512331326440

Maróti, P., Kocsis, B., Ferencz, A., Nyitrai, M., & Lőrinczy, D. (2020). Differential thermal analysis of the antibacterial effect of PLA-based materials planned for 3D printing. Journal of Thermal Analysis and Calorimetry, 139(1), 367–374. https://doi.org/10.1007/s10973-019-08377-4

Mcloughlin, M. (2020, March 23). Respiradores (y más) hechos en casa: Las impresoras 3D se movilizan en España. El Confidencial. https://www.elconfidencial.com/tecnologia/2020-03-23/impresion-3d-respiradores-mascarillas-biseras_2509855/

McManus, B. (2020, April 4). A Guide To Designing Low-Cost Ventilators for COVID-19. https://www.youtube.com/watch?v=7vLPefHYWpY

Morgan, D. (2020, January 23). ESD 560 Lecture 2: Sustainable Design Strategies.

Olieman, A. (2010, December 11). MET matrix. The Industrial Design Engineering Wiki - Technical University Delft. http://wikid.io.tudelft.nl/WikID/index.php/MET_matrix

Olieman, A. (2011a, May 2). EcoDesign checklist. The Industrial Design Engineering Wiki - Technical University Delft. http://wikid.io.tudelft.nl/WikID/index.php/EcoDesign_checklist

Olieman, A. (2011b, May 2). EcoDesign strategy wheel. The Industrial Design Engineering Wiki - Technical University Delft. http://wikid.io.tudelft.nl/WikID/index.php/EcoDesign_strategy_wheel

Orji, I. J., & Liu, S. (2020). A dynamic perspective on the key drivers of innovation-led lean approaches to achieve sustainability in manufacturing supply chain. International Journal of Production Economics, 219, 480–496. https://doi.org/10.1016/j.ijpe.2018.12.002

Oth, O., Dauchot, C., Orellana, M., & Glineur, R. (2019). How to Sterilize 3D Printed Objects for Surgical Use? An Evaluation of the Volumetric Deformation of 3D-Printed Genioplasty Guide in PLA and PETG after Sterilization by Low-Temperature Hydrogen Peroxide Gas Plasma. The Open Dentistry Journal, 13(1). https://doi.org/10.2174/1874210601913010410

Pearce, J. (2020). A review of open source ventilators for COVID-19 and future pandemics. https://doi.org/10.12688/f1000research.22942.1

Peinado, F. (2020, March 29). Madrid dice no a la solidaridad de los impresores 3D. El País. https://elpais.com/espana/madrid/2020-03-29/madrid-dice-no-a-la-solidaridad-de-los-impresores-3d.html

Peñarredonda, J. L. (2020, April 1). Covid-19: The race to build coronavirus ventilators. BBC. https://www.bbc.com/future/article/20200401-covid-19-the-race-to-build-coronavirus-ventilators

Pérez, E. (2020, April 5). Respiradores artificiales fabricados en España: Por qué su certificación es tan lenta cuando tantas vidas dependen de ellos. Xataka. https://www.xataka.com/medicina-y-salud/respiradores-artificiales-fabricados-espana-que-su-certificacion-lenta-cuando-tantas-vidas-dependen-ellos

Plocher, J., & Panesar, A. (2019). Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Materials & Design, 183, 108164. https://doi.org/10.1016/j.matdes.2019.108164

Protofy. (2020). Github shared folder of OxyGEN IP. GitHub Protofy Team / OxyGEN. https://github.com/ProtofyTeam/OxyGEN

Protofy. (2020a). OxyGEN project: About. New Website. https://www.oxygen.protofy.xyz/about

Protofy. (2020b). OxyGEN V14 Instrucciones de USO (Borrador) (OxyGENIP_V1, legal and tech docs). OxyGEN #HOPE; https://701f4afe-64ef-424a-8bec-754f5dc1ea0a.filesusr.com/archives/8a52d7_48b9089741654470a0c170b27e9b1a9a.zip?dn=Oxygen_IP.zip.

Protofy. (2020c). OxyGEN-IP V1.0 Exploded (OxyGENIP_V1). https://701f4afe-64ef-424a-8bec-754f5dc1ea0a.filesusr.com/archives/8a52d7_48b9089741654470a0c170b27e9b1a9a.zip?dn=Oxygen_IP.zip.

Protofy. (2020d). Proceso ensamblaje equipo ayuda respiración OxyGEN-IP (OxyGENIP_V1, legal and tech docs). https://701f4afe-64ef-424a-8bec-754f5dc1ea0a.filesusr.com/archives/8a52d7_48b9089741654470a0c170b27e9b1a9a.zip?dn=Oxygen_IP.zip.

Protofy. (2020e). Ventilator explo & views (OxyGENIP_V1). https://701f4afe-64ef-424a-8bec-754f5dc1ea0a.filesusr.com/archives/8a52d7_48b9089741654470a0c170b27e9b1a9a.zip?dn=Oxygen_IP.zip.

Proust, K., Newell, B., Brown, H., Capon, A., Browne, C., Burton, A., Dixon, J., Mu, L., & Zarafu, M. (2012). Human Health and Climate Change: Leverage Points for Adaptation in Urban Environments. International Journal of Environmental Research and Public Health, 9(6), 2134–2158. https://doi.org/10.3390/ijerph9062134

Rams, D. (1976). Design by Vitsoe.

Sherman, E. (2020, February 21). 94% of the Fortune 1000 are seeing coronavirus supply chain disruptions: Report. Fortune. https://fortune.com/2020/02/21/fortune-1000-coronavirus-china-supply-chain-impact/

Singh, S. N., Venkatesh, V. S. S., & Deoghare, A. B. (2021). A review on the role of 3D printing in the fight against COVID-19: Safety and challenges. Rapid Prototyping Journal, 27(2), 407–420. https://doi.org/10.1108/RPJ-08-2020-0198

Singh, S., Prakash, C., & Ramakrishna, S. (2020). Three-dimensional printing in the fight against novel virus COVID-19: Technology helping society during an infectious disease pandemic. Technology in Society, 62, 101305. https://doi.org/10.1016/j.techsoc.2020.101305

Sosnowski, E. P., & Morrison, J. (2017, May 23). Sterilization of medical 3D printed plastics: Is H2O2 vapour Suitable? The 40th Conference of The Canadian Medical and Biological Engineering, Winnipeg. https://pdfs.semanticscholar.org/11a1/dae1004e352335b234f48eee292032003bb5.pdf

Spanish Agency for Drug and Medical Device & Spanish Healthcare Ministry. (2020). Autorización de investigaciones clínicas para ‘Estudio RES-COVID: BALÓN RESUCITADOR AUTOMATIZADO MECANIZADO COMO ALTERNATIVA A LA COMPRESIÓN MANUAL PARA LA VMI DE PACIENTES EN SITUACIÓN DE ALARMA: PROTOCOLO DE USO COMPASIVO’.

Stappers, P. J. (2003). Generative tools for context mapping: Tuning the tools. 6.

Temple, J. (2020, April 1). Gracias, impresión 3D, pero no todo vale para combatir el coronavirus. MIT Technology Review. https://www.technologyreview.es/s/12065/gracias-impresion-3d-pero-no-todo-vale-para-combatir-el-coronavirus

United Nations. (2019). Sustainable Development Goals Report 2019. https://unstats.un.org/sdgs/report/2019/The-Sustainable-Development-Goals-Report-2019.pdf

Vall-Llosada, C., & Marco, B. (2020). SEAT arranca la producción de respiradores de emergencia en su fábrica de Martorell.

Visser, F. S., Stappers, P. J., van der Lugt, R., & Sanders, E. B.-N. (2005). Contextmapping: Experiences from practice. CoDesign, 1(2), 119–149. https://doi.org/10.1080/15710880500135987

WHO. (2020). Coronavirus disease 2019 (COVID-19) Situation Report 81 (No. 81). World Health Organisation. https://reliefweb.int/sites/reliefweb.int/files/resources/20200410-sitrep-81-covid-19.pdf