Teaching strategies for product design using biomaterials

Introduction

Our link with materials dates back to prehistoric times, over the centuries the elements present in nature have been intervened to become tools with the aim of improving society's skills and opportunities. Through experimentation, observation and analysis, it has been possible to delve into the characteristics of each material’s specific characteristics, and consolidate a kind of universal knowledge around them. In turn, with the advancement of technology, the concretion of said elements has been optimized, but this exponential growth has also given rise to the excessive exploitation of available resources, something that is currently becoming more visible due to its negative impact in the ecosystem.

Already at the first Design Schools, such as Bauhaus and Vchutemas, design projects were traversed by certain thematic axes such as: morphology, usability, function, materiality and context, among others. While all of them co-exist on the design project cycle, the depth with which they are addressed may differ in terms of the pedagogical objectives that are set for each instance. In the industrial design field, the exploration of the characteristics, properties and possibilities that arise within the material universe to materialize the design of tangible products, is considered part of the disciplinary knowledge.

During the main instances of learning the design process, students incorporate knowledge through their own experiences in the development of models and prototypes of the projected objects. Due to the high cost that the elaboration of a prototype with real materials can represent, it is detected that in the learning instances many students have moved away from the true material experiences. As a result, they do not have a base of exploration and technical knowledge regarding the opportunities that a material can provide to their projects.

While the role of Industrial Design has varied during recent years (becoming more and more associated to the digital transformation industry), as far as product development is concerned, it becomes both more necessary and strategic to reflect upon the environmental impact generated by materiality decisions that are made when designing a product of any given scale.

Designers should study in depth the materiality of their projects in order to provide a harmonic response to current needs, which takes into account the environment, limiting the exploitation of natural resources and providing alternatives, both in products and in the materials themselves. For all this, design with biomaterials represents an opportunity to train students' material sensitivity, in an accessible way and bringing some current notions of this branch of the disciplinary knowledge.

About biomaterials

Biomaterials are usually described from a medicinal perspective as those that a living organism can tolerate. Their application for the construction of prostheses and highly complex products in the healthcare field is well known. In this case, they can either be naturally biological materials, such as wood, or other elements with the ability to integrate into the body to fulfill certain functions. Nevertheless, there are also artificially originated biomaterials, such as polymers, ceramics and metals.

The first biomaterial, in the sense in which the term is known nowadays, was developed during the 1920s. Reiner Erdle and Charles Prange combined their knowledge as a dentist and metallurgist, respectively, to develop the first metallic biomaterial: the Vitallium alloy.

Biomaterials can be grouped into three types:

- Metallic biomaterials: they are used to create implants and prostheses. This group may include titanium, chromium or cobalt alloys, among others.

- Ceramic biomaterials or bioceramics: These are used to shape prostheses or implants when they do not need to support a high load. They are frequently used in dental implants and orthopedic surgery.

- Polymeric biomaterials or bioplastics: They are classified into two large groups, natural polymers and biocomposites.

Natural polymers are those that come directly from the plant or animal kingdom (silk, wool, cotton, cellulose, starch, proteins, natural rubber latex or rubber, nucleic acids, among others). They follow the grow it yourself premise. Materials made with mycelium, scoby, roots, and yeast fall into this category. These materials have their own growth and development time, sometimes very long, and it is for this reason that they are excluded from our methodological proposal, limited by a short and rigorous academic calendar.

Biocomposites, which could be said to follow the premise cook it yourself, are made from biopolymers, that is, natural polymers produced by the cells of living organisms. Collagen, cellulose, starch, gelatin, alginate, and carrageenan are examples of this.

If we add what we call load to the biocomposites, we finally find ourselves within the framework of our proposal for the incorporation of biomaterials into the teaching of Industrial Design. Some examples of loads can be shells, seeds, charcoal, pulp, dried flowers, fibers, mate, and coffee.

Apart from the cut of bioplastics within the universe of biomaterials, another significant cut that was made to carry out the exercise refers to the obtaining of raw materials that will be used to create new materials. Since we belong to a public institution, it is our premise that the exercises can be carried out in an inclusive, ethical and accessible manner; this is why it was proposed to work only with organic discards from non-eatable domestic use.

Biomaterials in the current context

Leaving behind the post-industrial era, seeing the information age unfold before us, we can recognize a change in the productive scale, which leaves behind massiveness to move forward to a more specific production. This is reinforced not only by the increasingly accessible production tools of the CAD-CAM type, the 3D printers, the do it yourself culture, and the open design concept, which not only allow a lower scale production, but also the participation of communication platforms that make course to a greater dissemination of small-scale productions.

It is in this context where digital processes approach the designer and the figure of the designer-maker that biomaterials emerge as part of the explorations that are of interest to the discipline.

It is particularly interesting to review and understand how Industrial Design is taught in this context and what link with these technologies we have from within a public institution such as the University of Buenos Aires. Although more and more spaces become available, such as prototyping centers and fab labs, we highlight one of the values that we believe to be the most interesting about biomaterials: their availability.

Some references on the application og biomaterials in industrial design

Although biomaterials is a topic that is already well associated with product design in some fields of application, it has only recently been incorporated into the teaching of Industrial Design. Some examples of institutions that also work on these challenges are the Universidad Austral from Chile, which under the guidance of LABVA has carried out experiences on the subject during the last years.

Another case that has been observed is that of the RMIT University, in Melbourne, Australia. A workshop on the design of products with mycelium is carried out there. All students must work with that same material, cultivating it at home and in the University laboratory. After experimenting with this fungus and observing its characteristics, students make speculative design proposals. The goal of this workshop is to encourage future designers to experiment, observe and study these materials in order to come up with innovative solutions.

From a commercial perspective, there are several proposals for disposables made from cornstarch, wheat semolina, and sugar cane. Some of the importers in Argentina are Natural Pack, Ecotown, Biopackaging and Biopack. However, these are not fully biodegradable, since in many cases they contain PLA, which cannot biodegrade without going through an industrial process. It takes at least 80 years for PLA to break down in the open air, contributing to environmental pollution from plastic and especially micro plastics, in addition to conventional plastic from crude oil both at sea and on land.

In Argentina, we do not have entities that regulate biodegradability since at the moment there is not a high demand for products made with biomaterials. There are few enterprises that develop biodegradable products and which have reached an instance of industrial production. The entities that are in charge of regulating or certifying products for sale (such as the ANMAT and the INPI) do not yet have regulations to certify products made with biomaterials. However, 3 years ago a government distinction called the Argentine Bioproduct Seal was launched. This seal ensures the biodegradability of products made from biomaterials, as it verifies that their composition is organic and their ingredients compostable.

The need to certify arises as the main actors move forward in becoming and establishing themselves as companies, giving rise to other ventures in the same category. In Argentina, few actors are venturing into this niche of biodegradable products. Some examples are ODA biovajilla (bio crockery) and Fungipor. ODA consists of biodegradable disposables and could become the first Latin American company to manufacture on a large scale. Fungipor is a company that is making strong progress in developing mycelium packaging.

Most of the ventures that develop products with biodegradable materials are in an experimentation stage. Few are taking the first steps towards real industrial production. This is because working with organic biomaterials entails a variable control process (climate, temperature, pressure, chemical compositions) which are being studied in order to stabilize recipes and produce on an industrial scale. In addition, profitability is a great unknown, since there is no guarantee that industrial manufacturing with biomaterials will be a profitable business.

The university of Buenos Aires faculty of Architecture, Design and Urbanism

Founded in 1821, the University of Buenos Aires (UBA) is Argentina's largest university. Non-tariffed (it depends financially on the Argentine state, but is autonomous), free and secular, it is considered to be one of the most prestigious study centers in both America and the world. It has thirteen faculties, one of which is that of Architecture, Design and Urbanism where, ever since 1985, the Industrial Design master’s degree is taught. The project presented here is part of the research carried out by a team of teachers from the Industrial Design Workshop of the Sanguinetti Chair, in the career that is taught at FADU, UBA.

The Industrial Design Workshop constitutes the main axis in the training of the students of the career, since it represents the meeting place of all the knowledge acquired in the other subjects. It is carried out in five levels (one for each year that the degree lasts) dictated by each Chair in continuity. The weekly workload is of six hours, divided into two classes per week. The aim of the course is for students to learn to design through practical project exercises, known as practical work. These exercises represent simulations of product development, very diverse both in their approach and in complexity. The teachers' task is to assist and guide these projects, understanding the reasons that lead each student towards making certain decisions and providing the necessary theoretical content to support the method proposed by the Chair. Each course is composed of several practical works that culminate in the delivery of the material requested for each case (product drawings, descriptive memory, technical plans, three-dimensional models, among others).

The practical work of the Industrial Design Workshop is equivalent to what Donald Schön calls reflective practice (or practicum), true learning exercises through reflection in action:

“The work of the practicum is carried out by means of the combination of learning by doing of the students, their interaction with the tutors and the other classmates, and a more diffuse process of experiential learning. Students have to learn a type of reflection-in-action that goes beyond existing rules, not only by establishing new methods of reasoning, but also by constructing and testing new categories of knowledge, strategies of action, and ways of formulating the challenges”. (Schön, 1987, p. 46).

The Sanguinetti Chair of the Industrial Design Workshop (in its five annual levels) is oriented towards approaching new disciplinary challenges originated in new design scenarios. These challenges account for the current expansion of the field of action of Industrial Design, a consequence of the incessant technological innovations, but also of the interdisciplinary practice, typical of the professional profile of the contemporary industrial designer. The crossing of knowledge that the interdisciplinary approach supposes generally finds the designer assuming a role of articulation, having to assimilate new approaches that deserve to be incorporated into the career’s study plan. Project exploration with biomaterials represents one of these new disciplinary scenarios. Undoubtedly, it is of particular interest to the Chair to address its treatment within the framework of the didactic exercises developed in the faculty workshops.

Why incorporate biomaterials into industrial design teaching?

The incorporation of biomaterials in the teaching of Industrial Design is part of the first year of the degree, in the first level of the Industrial Design Workshop of the Sanguinetti Chair. Throughout this period, work is done on simulations of product generation from different approaches (morphological, functional, semantic, usability, etc.). These exercises progressively become more complex and gradually integrated.

Since 2014, similar exercises have been carried out at the initial level of the workshop, which ponder the material exploration for product design. The experiments carried out integrated materials such as wood, Tyvek, cement and since 2018, it was decided to start working with biomaterials.

A particular feature of learning in the generation of objects is empirical exploration. Knowledge is not acquired by mere transmission from the teachers, but rather it is built from reflection on what has been done. Not only from their own experience, but also from that of others, since both the process and the results are shared and discussed with their peers in different spaces, turning learning into "cooperative learning". (Perkins, 2008, p. 52).

In the passage from ideation to the realization of a project, it is important to explore the material. The constant three-dimensional simulation of what is going to be done allows for observations, corrections and verifications in order to be able to carry out the project in the more adequate way. We revisit practices that come from anthropological concepts, creating objects from a necessity instead of creating needs to come up with objects, which are often obsolete. Being sensitive from within the materiality invites us to design with the necessary awareness that each situation demands.

Although the materiality of the products is addressed in all the practical exercises, it is essential to include biomaterials as viable raw materials, also responding to environmental problems. It is a paradigm shift in which biology is taken for a new technology. We aim to create materials that nurture local economies and ecologies by reaching thought-provoking solutions. The goal is to encourgae students’ material related sensibility. New technologies, such as 3D printing, make students move away from a sensitive verification stage. There is an absence of real handling of the materials, which prevents them from knowing in depth what is being designed. This way, the incorporation of biomaterials as a subject of study gives students the possibility of a review from within the senses in the learning process. The connection is given by a progressive learning, a respectful follow-up in relation to what the material allows and a slow observation that provides a new wisdom: design from the possibility that the material offers. The exercise proposes not only designing with biomaterials, but mainly designing the material itself.

In addition to the design nature involved in the development of a material from its composition, another important factor that must be taken into account is the environmental impact. Sustainability is already a crucial requirement and the role of designers is to be aware of it by acting as agents of change, responding to future problems in the present.

The practical exercise of product design based on using biomaterials poses a particular challenge, mainly due to the fact of including the elaboration of the material in the design process. These elaboration instances are essential if the aim is to generate a strong commitment to learning and discovering the intrinsic qualities of the material. There is a combination of thoroughness and exploration in this way of approaching the design process, something that is of particular interest to the professorship.

The development of a biomaterial within the product design process adds stages such as the analysis of the components to be combined, whether they are natural materials or ingredients, additives and load. It also invites us to think about how to link them, whether it be by braiding fibers or random arrangements, by compression or blowing, among others. Studying and understanding the properties of the raw material to be combined becomes essential (its acoustic possibilities, tensile strength, impermeability, etc.) Elaborating the material gives students a different sensibility in the integral design process, perhaps deeper than when it is projected with traditional materials. Therefore, it is important to reach a molecular level compromise with the object of design. The load, its collection, the justification of it according to its availability, the way it is integrated, whether it is crushed, ground or chopped, its color and texture become one of the topics of greatest attention within the exercise.

Methodology

The design process in the industrial design workshop

“An important part of what a student who begins a practice such as design needs to learn cannot be understood before they begin to design. They must begin to design in order to learn to design” (Schön, 1987, p. 150).

The design process that students usually go through in the product design exercises at FADU's Industrial Design Workshop is based on five stages that are described below:

- Research: stage referred to the survey and analysis of relevant cases, as well as reference concepts. Here the available resources must be identified, both in technological-productive terms, and in relation to the project times. The research stage must be characterized by a critical and reflective spirit, obtaining in an organized way a series of conclusions on each of the analyzed aspects.

- Conceptualization: in this stage, the project intentions are expressed and organized. Different schools have used different terms to refer to ideas and their project organization: parting point, guiding idea, design program, strategic plan, conceptual map, among others. Any terminology will be useful if it facilitates the visualization of the concepts involved in the project and their hierarchy.

- Generation of proposals: it is the stage where designers materialize their ideas. These can be presented both through drawings, as in three-dimensional models or prototypes, but they will generally have a schematic resolution, where it is important that the nature of the proposed solution is clearly understood.

- Product development: it is the stage of the project where the technical knowledge of the designers is put into practice. With a perspective of approximation to each part or sector of the product, the designers proceed to define each factor in order to bring it closer to a state of real feasibility.

- Transfer design: when the products are already defined in detail, it is desirable for the designers to take care of projecting the actions, as well as the necessary instruments, for their transfer and implementation. Here traditional formats can come up (technical plans, digital files, descriptive reports, among others), as well as new ways of documenting the project.

Generally, the encounter with the resolutions in each project stage causes the need to modify some decisions made in previous stages. Therefore, each stage of the process implies a review of the previous one. This action is called iterating, and it is typical of the industrial design process.

This generic process consisting on five stages, usually implemented in the product design exercises of the Industrial Design Workshop at the Sanguinetti Chair, marks the basis on which the methodological proposal for the development of the practical exercise on working with biomaterials was elaborated, and which is described in the next few paragraphs.

Steps for learning in design with biomaterials

The objectives on which the proposed methodology is structured can be summarized in three complementary approaches. In the first place, it is interesting to bring students closer to materials, their properties, their transformation possibilities and their possibilities of application in a product. Secondly, it seeks to promote experimentation. The empirical -both personal and collective- exploration, as well as the permanent reflection on what has been done, strengthen the project process as the fundamental aspect in the students’ production and in the construction of knowledge. Accompanying what Edith Litwin calls "the search for autonomous-critical students" (1997, p. 78). A third objective, but no less important, is the incorporation of the notion of designers as agents of change, in this case, from an environmental and productive point of view.

Students design a biomaterial individually, which they then apply to a specific product, also designed by them. The workshop-type work proposal implies constant collaboration between all the participants, multiplying the approaches, increasing the diversity of views. This way, the process and personal experience are nourished by the contributions of the processes and experiences of others, enriching the learning instances and promoting the construction of knowledge.

The monitoring of the processes and results of the exercise is carried out in three ways:

- Instances of evaluation through both partial and final deliveries, which make it possible to make up an idea of the status of the project at different times.

- Instances of direct observation, through tours carried out by the teachers along the workshop during the classes, and which allow evaluating and guiding the activities at the moment they are carried out (while in the virtual classroom, this is carried out in different collaborative work platforms used by the Chair).

- Instances of direct exchange between teachers and students through dialogue, which makes it possible to investigate and delve deeper into some specific aspects.

Stages and activities

The exercise is divided into two clearly defined stages. A first instance focused on the research and development of the biomaterial, and a second one dedicated to its application in product design. In turn, each stage consists of several scheduled activities. Each stage and each activity have specific objectives, particular tasks, application tools and specific evaluations, designed according to the needs of each instance. The stages and activities are described in detail below.

Stage 1: Research and material development (4 activities)

This first stage consists of research into the world of biomaterials, analysis and reflection upon the subject, to later arrive, through praxis, at the generation of a biomaterial from which a deep knowledge is obtained regarding its characteristics and behavior. Divided into four weekly activities, this stage encourages experimentation and observation, allowing theoretical content to be related to reflective practice.

The proposal addresses the empirical exploration using resources that students have available at home. We work mainly with non-edible food discards. The use of these materials allows us to re-elaborate and re-signify the notion of “waste”, turning what is considered useless in a given context into an element with which to produce material and symbolic goods. On the other hand, and for the specific purposes of this type of activity, the use of this type of material (consumed at home) allows and facilitates access and availability by students.

ACTIVITY #1:

BIOMATERIAL RESEARCH

It is the first approach towards concepts, terminology, background, what exists and the vacancies, possible applications, the experiences of other students, and readings on the subject. All aspects that are fundamental in order to understand and define both the object of study and the theoretical framework. These inquiries, reflections and conclusions are the ones that are then discussed in groups. The interactions with other approaches and other looks allow a rereading of what has been done.

The teachers, if necessary, can propose a series of questions that guide the investigation to unexplored places or, simply, to deepen the analysis. The productions are compiled to be shared with other students. Students can show their work however they prefer, allowing them to decide the way of communicating their ideas: maps, diagrams, texts, images, materials, are some of the possibilities.

To order and guide the research, work is proposed on three axes: 1: the analysis and investigation of concepts and terms; 2: the analysis and research of references; 3: drawing conclusions. These axes do not exclude others that may be proposed by students.

Suggested questions to address activity #1: In what fields are biomaterials being used? What is it that exists? What is interesting about what exists? Are there any unexplored biomaterials? Is it possible to carry out a classification or categorization?

ACTIVITY #2:

BIOMATERIAL EXPERIMENTATION

Once the research stage is advanced, a second instance is presented where students begin to explore and experiment the generation of biomaterials. The first approach occurs almost intuitively, since the previous knowledge is incorporated, mainly, in their own research. This initial approach favors exploration without restrictions or conditions, allowing a wide and varied exploratory search.

Concepts typical of the generation of materials are incorporated here: load, additives, binder, plasticizer, integration, among others. These terms favor order and classification during the initial approach, since they allow students to translate into words the decisions they make in their exploration. Selecting and dosing loads, binders, additives, or considering cooking, drying, or integrating, are aspects that students must evaluate to begin building their empirical knowledge regarding the obtained results.

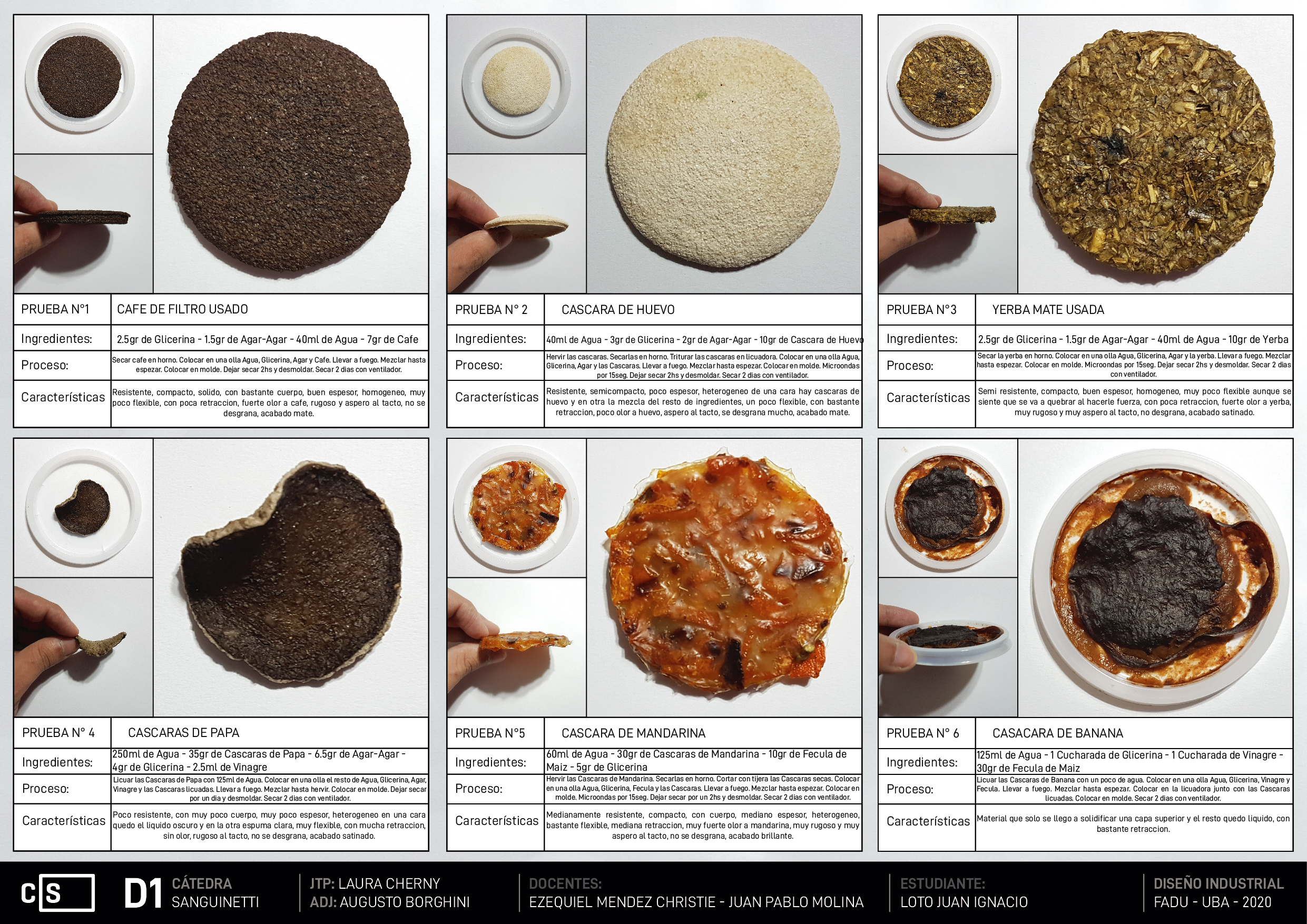

To guide the task, we propose the generation of six materials on which the respective ingredients and production processes can be registered, shaping true recipes, combining the variables and concepts students have worked on. Reflections and conclusions should be elaborated on the obtained results. The presentation is made using the technical sheets provided by the Chair for six alternative materials (figure 1).

Figure 1: technical sheet for six material explorations (student: Juan Ignacio Loto, Industrial Design Workshop 1, Sanguinetti Chair, FADU – UBA 2021).

These sheets show the samples (the material) with the description and quantity of ingredients used, as well as the process carried out to obtain it (the recipe). The samples provide information regarding the sensitive characteristics of the material, how it looks, its textures, colors, finishes, how it smells, its aromas, the sensations it produces when touched, even the sounds involved in it. On the other hand, the description of the ingredients and the quantities or proportions used allow knowing its composition so that it can be replicated or even modified. In addition, the description of the production process shows the minute detail of the steps to follow in order to obtain the material: sequences, temperatures, stage times, actions, utensils or necessary tools. There are also reflections, conclusions, observations or qualities detected on the sample obtained, or even on the production process: status changes, environmental influences, variations in physical characteristics, etc. These sheets allow systematizing the information and making it easier to have a clear record of what has been done, in addition to allowing comparison with the productions of other students. Although they function as an ordering synthesis of what has been generated, the continuity of the process logbook is also suggested.

The Chair encourages keeping a logbook as a record of the carried out explorations. This, of a personal nature, contains everything that has been developed throughout the process. Each test, data, conclusion, idea, material and decision made feed this log. It becomes a very useful tool for constant consultation throughout the project.

Suggested questions to address activity #2: What transformations can be detected from the original load? Was there a change in pigmentation? Was there a change in aroma? What physical capacity does the material adopt after being processed? How do the operations performed on the load affect the final result?

ACTIVITY #3:

PROPOSALS FOR BIOMATERIAL GENERATION

This instance is characterized by the convergence and deepening of the previous explorations. After the first approximation to the elaboration of biomaterials, a less intuitive and more reflective search on the path to follow is given way. Based on the obtained results, the decisions are reviewed and those that are of interest are delved into, looking for alternatives for a single material chosen from the six made for the previous activity.

The multiplicity and diversity of the initial tests converge in new, more developed samples. Modifications of small variables in the composition (percentages of ingredients, load, additives, etc.) or the biomaterial manufacturing process (drying times, material thickness, etc.) are aspects to work on during this instance.

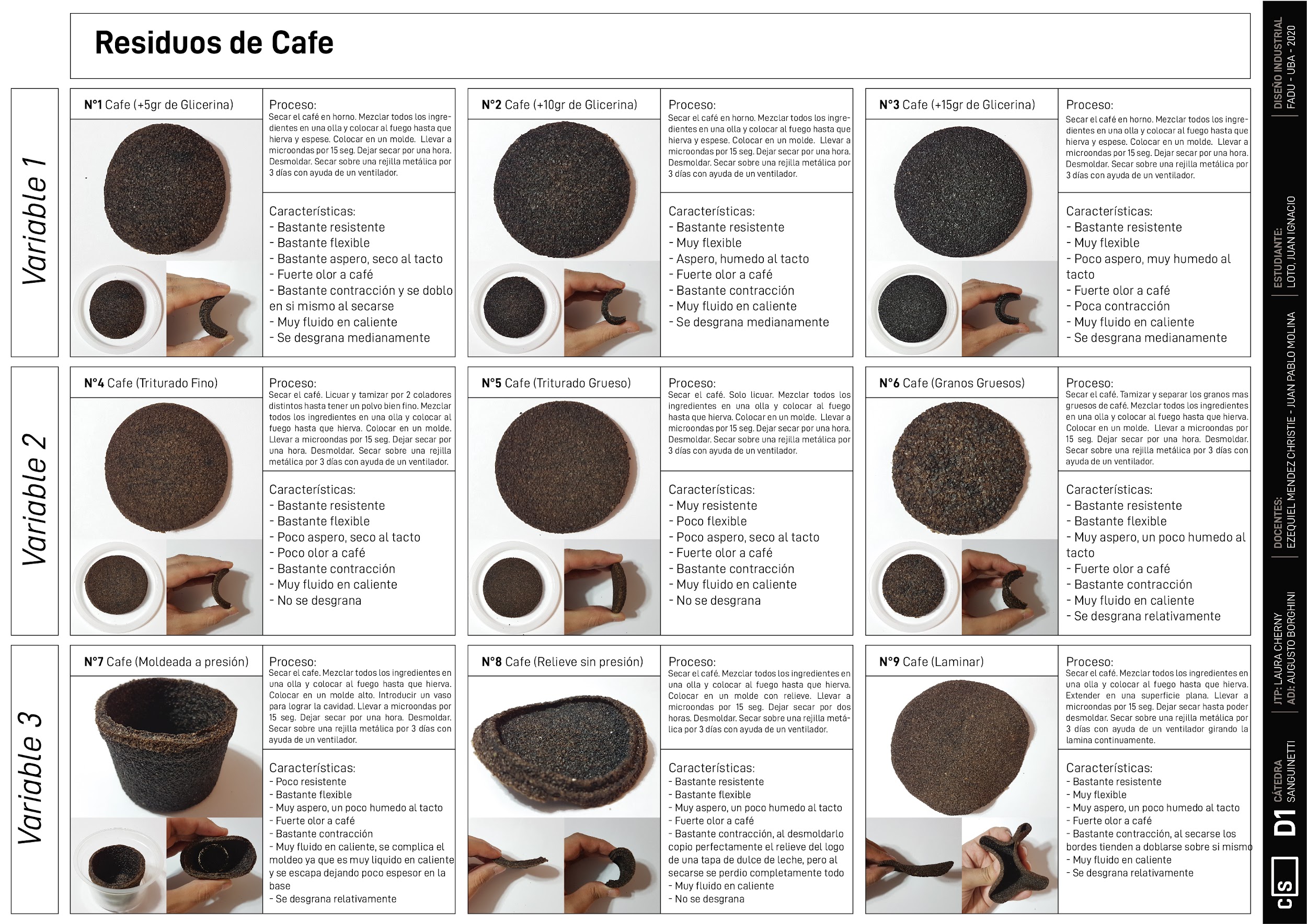

In order to guide the process towards a deepening of the elaborations, the production of nine samples is proposed. For this, the Chair developed a sheet (see figure 2) where students can catalog the different generated alternatives.

Figure 2: technical sheet for nine alternative samples (student: Juan Ignacio Loto, Industrial Design Workshop 1, Sanguinetti Chair, FADU – UBA 2021).

Suggested questions for approaching activity #3: What changes are manifested as of the modification of proportions of each component? What changes are identified by intervening the drying variables? What are the characteristics of the individual components, and what are those of the result of their combination?

ACTIVITY #4:

CHOICE AND DEFINITION OF BIOMATERIAL

This instance of the exercise functions as a closure of the research and development stage of the biomaterial. Here, each student selects one of the elaborated recipes to continue the exploration as from the possibilities that this material offers. At this point, the reproduction of the recipe and mastery in production are essential. But so is experimentation on a larger scale. The students test their preparations here by modifying the production scale, both in terms of time and quantity produced, which results in the ratification or modification of said recipe.

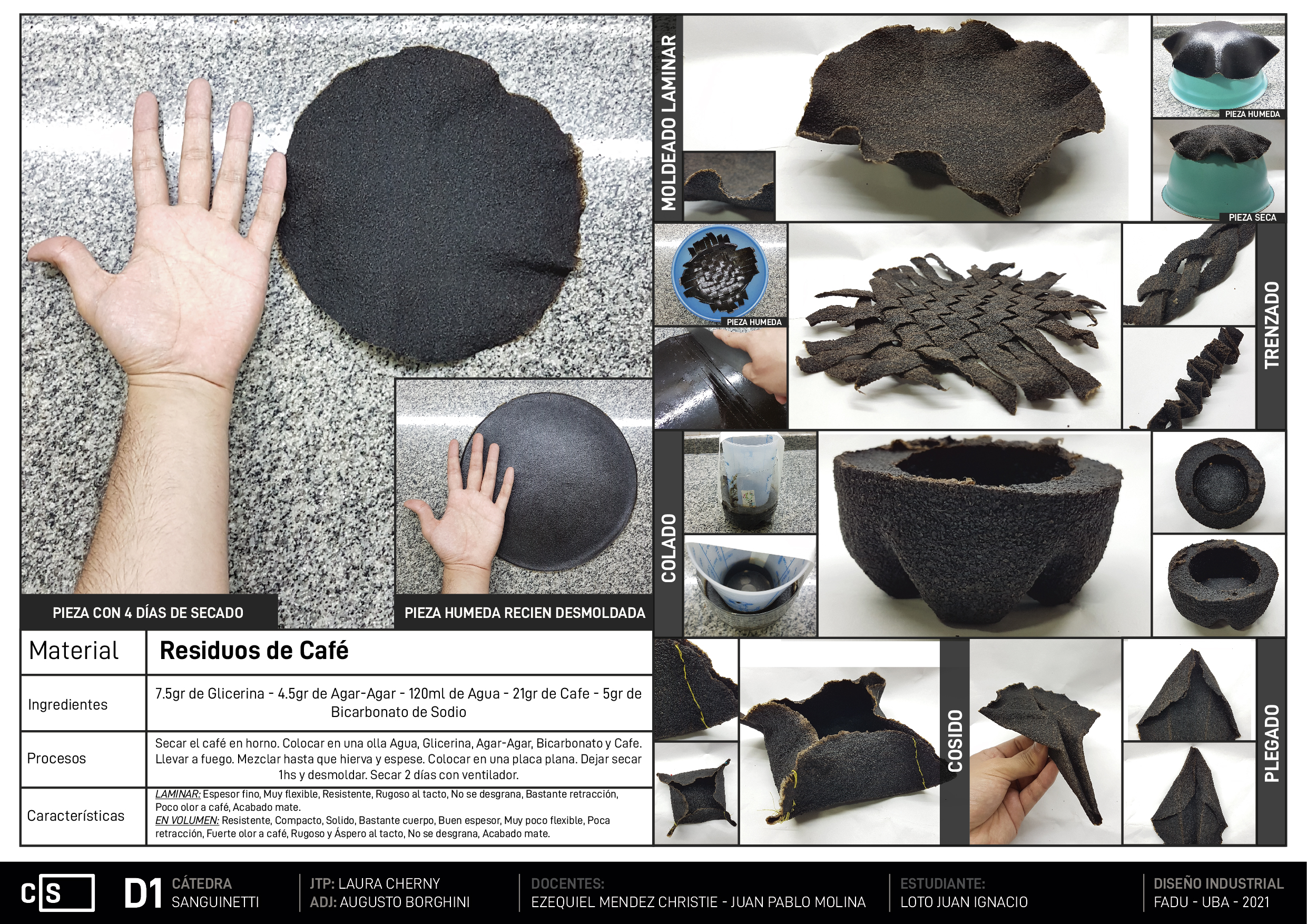

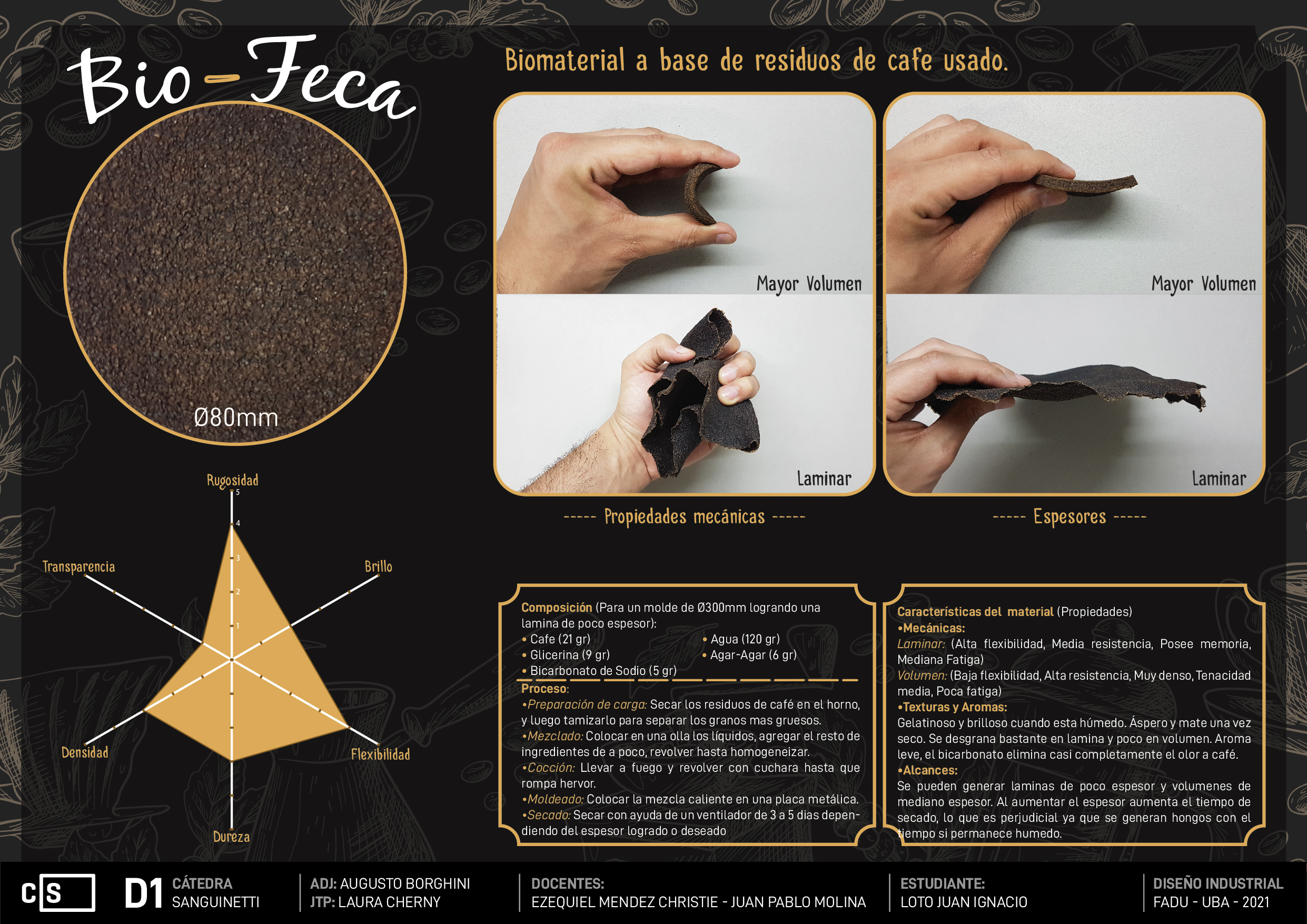

In parallel to the investigation of the scalability of the biomaterial, we propose the morphological and technical exploration. Experiencing the configurations that the material allows, the shapes, textures and smells, the physical characteristics, but also what it transmits from a symbolic perspective. To present these explorations, students can use the morpho-technological presentation sheet (figure 3).

Figure 3: technical possibilities sheet (student: Juan Ignacio Loto, Industrial Design Workshop 1, Sanguinetti Chair, FADU – UBA 2021).

Lastly, the elaboration and exploration of a material sample and three approaches of its technical and morphological possibilities are proposed. The way to present it is through the use of sheets (see figure 4) and the logbook. On this occasion, the sheets contain a description and conclusions of the configurations together with each test’s samples. The description of the configuration and the process of elaboration of the configurations allow knowing and replicating the steps carried out to obtain the proposed biomaterial: sequences, interventions on the materials, ways and elements used for bonding, temperatures, stage times, utensils or tools used, etc.

Figure 4: final presentation sheet for stage 1 (student: Juan Ignacio Loto, Industrial Design Workshop 1, Sanguinetti Chair, FADU – UBA 2021).

On this occasion, too, the reflections, conclusions, observations or qualities detected on the tests provide additional information on the configurations or the manufacturing processes, beyond the presented samples. These material samples work as physical evidence of the students’ explorations. The Chair also encourages the making of an audiovisual record where the processes of elaboration of the material can be accounted for.

Since activity #4 concludes the first stage of the project, the evaluation of the students' productions is carried out. This evaluation is based on four criteria:

- Project process: it refers to the elaborations and explorations carried out by the students, the depth they reached, as well as the conclusions and decisions they made, in addition to the contributions and exchanges with other students.

- Survey and analysis of the topic: how much each student knows about the object of study.

- Development of the manufactured biomaterial: exploration and handling of the recipe, and of the scale of the technical and morphological possibilities of the material.

- Quality of the project presentation: the way they communicate and convey their ideas.

Exploring and deepening the material possibilities is of vital importance when facing the design of a product. This instance, then, is not only the closure of the first stage, but also supports the next one, that of application of the material.

Suggested questions for approaching activity #4: Can it be transformed? Can it become a filament, a sheet, a volume? Is it flexible? Is it rigid? Does it have resistance to impact? Can it be cut, glued, drilled, painted? Does it smell? What is it like to touch it? Is it opaque or translucent? Which settings does it allow? What sensations does it transmit? Was the exploration deep, conscious, pertinent? How were the decisions made? Did they come from experimentation? Was there significant progress in the project? What was the process like? Was it based on personal search? Was it nourished by the exchange with others, by theory, by other people's experiences?

Stage 2: Applications of the biomaterials to the design of new produdct (3 activities)

At this stage, the central axis is the application of the biomaterial to the design of a new product. After exploring and learning about the developed material, in both its elaboration and its morphological and transformation possibilities, the students design a product. Divided into three activities, this stage proposes a route already known by the students: to work on a product design methodology that goes through research, the generation of concepts and proposals, up to the detailed development of said product.

The design and development of an object is proposed, the choice of which is subject to the particular characteristics of the produced materials. The product, in all its aspects, must consistently respond to the material properties. The choice of the object to design can be defined either by the Chair or by the students. We propose working on the development of products of small dimensions and within contexts to which students can have access. This facilitates experimentation and reproducibility of what they generate. However, the exercise can also address products of diverse scales and contexts.

ACTIVITY #5:

PRODUCT ANALYSIS AND PROPOSAL GENERATION

Once the product to be designed is defined, we give way to the research instance around it: its characteristics, uses, contexts, users, referents, background and all those aspects that each student consider relevant. A deep observation of the objectual and symbolic world in which the product will be immersed is expected. In parallel, and contemplating the results and conclusions of this research, the investigation continues on the possibilities offered by the biomaterial from its technical, morphological and configurative characteristics, since, from these, the first design proposals will be generated. The biomaterial is the base on which the product will be consolidated.

Continuing with the exploration and experimentation carried out on the previous stage, this activity focuses on the generation of proposals from within the material practice. Students have the knowledge and access to biomaterials, and master the recipe and its possibilities of transformation. Again, here, the approach is of a divergent type. The variety and multiplicity, both of material explorations and design proposals, will allow students a greater analysis and reflection of what has been produced. The photographic, audiovisual, written and material record are the inputs that continue to feed the personal logbook.

Suggested questions for approaching Activity #5: What is the product's function? How does it conform? What uses is it given? Who uses it? When, where? What other products is it related to? What sensations does it transmit? What meanings does it have? How is it related to the produced biomaterial? How does it relate to formal possibilities or settings?

ACTIVITY #6:

PRODUCT DEVELOPMENT

This instance is characterized by working on the verification of what has been produced, to move on to the choice and definition of one of the explored paths. After an instance of opening and multiplication of proposals, the convergence of the productions continues until reaching a definitive design. For this, the corroboration of what has been produced is promoted through the production of study models or prototypes. These function as a test platform to check structural, formal, dimensional and functional issues, to verify the behavior of the biomaterial, the links and relations between parts, as well as to analyze the tangible and intangible relationships that exist with the users. From the verification of these aspects, we obtain information on which to reflect and be able to make decisions that allow convergence in a single proposal.

Once the path to follow is defined, we propose to move forward and delve into the constructive and productive details. Designing and developing anchors, supports, joints, encounters, edges and surface finishes, as well as accurately defining the dimensions, shapes, parts and proportions.

As well as in the previous activities, the photographic, audiovisual, written and material record of everything experienced and produced is recorded in the project logbook. This is the constant consultation tool when advancing on the definition of details, since it shows all the diversity of options traveled.

Suggested questions for approaching Activity #6: What, of what was proposed, works? What positive aspects does it have compared to the discarded alternative proposals? What negative aspects does it have? Why? Is it possible to replicate it? Does it meet the stated requirements?

ACTIVITY #7:

FINAL DESIGN ADJUSTMENTS

As a last instance, we work on the refinement of the product, delving into the development of its details. The conclusion of this exploration translates into the realization of a final prototype that works as a synthesis of a design process that began with the elaboration of the biomaterial. The explorations, inquiries, conclusions and decisions, both of the biomaterial and of the product, are reflected in this final piece. In addition, work is being done on the project's communication. Through the graphic presentation, the main idea, the paths followed, and the result achieved (biomaterial and product) with their particular characteristics are shown in a synthetic way. The logbook, as a documentation and recording tool, provides information on the process carried out by each student.

In this closing stage, a new evaluation of the productions is carried out. This evaluation is also based on four criteria:

1. Project process: it refers to the elaborations and explorations that were carried out, the depth that was reached, the relationships between biomaterial and product, the conclusions and decisions that were made, the results traveled and achieved, the conscious search by the students, the contributions and exchanges with other students.

2. Survey and analysis of the product to be designed: how much knowledge there is of the objectual and symbolic world in which the product and users operate.

3. Development of the product and the relationship with the biomaterial: here the exploration and handling of the biomaterial, its technical and morphological possibilities, and its application to the product are evaluated (relevance is a key aspect at this point).

4. Quality of the final presentation: what and how the project is communicated and transmitted, as well as the synthesis, hierarchy, reading levels and clarity of the information.

It is necessary to point out, especially for the evaluation instance, the importance of the existence of a supported feedback and, preferably, a narrative by the teaching team. The exposition and clarification of what was observed during classes and activities, the exchange of group and individual processes with the group of students, the results obtained according to the objectives sought and the criteria used, are aspects that are part of the learning process, which allow each student to continue reflecting on what they have learned.

Suggested questions for evaluation at the end of Activity #7: What level of relevance does the material have in the application in the product? Is it significant? Would the product be very different with another material? How is the morphological search (shape, textures, colors) in relation to the material and the product? Is it coherent? Was the development of details addressed? Is its resolution consistent with the biomaterial's characteristics? Was the exploration deep, conscious, pertinent? How were the decisions made? Did they come from experimentation? Was there significant progress in the project? How was the process? Was it based on personal search? Was it nourished by the exchange with others, by theory, by other people's experiences?

Results

Pilot experiences 2019, 2020 and 2021

Within the framework of the Industrial Design Workshop 1 (corresponding to the first year of the Industrial Design career at FADU, UBA) a practical exercise of designing products with biomaterials was carried out. It had three editions, in the 2019, 2020 and 2021 academic years, and it still continues (in the 2022 cycle it will be held for the fourth time).

The proposed modality was a face-to-face workshop type, distributed over two class days per week. An average of 65 students participated in each edition of the exercise. The projects were carried out individually. The design process in these experiences was structured based on the methodology described in the previous pages as a methodological proposal, so that two stages were followed, stage 1: creation of the material and stage 2: application of the material to the design of a product. The duration of both stages was a total of approximately 23 classes.

This exercise focuses on experimentation, downplaying the final results, therefore it was essential during its implementation that each student perform all the experiences corresponding to each stage. Such was the confidence of the teaching team on the fact that apprenticeship would be a consequence of the experience, that the following evaluation criterion was established at the beginning of the exercise: those who went through the entire process programmed by the Chair, would have passed the exercise, minimizing the importance of the final designed product’s performance.

2019: First experience

The 2019 experience carried out face-to-face in the workshop constituted a fundamental basis for what took place in the following years. The guidelines defined by the teaching team had a special focus on experimentation. Although all the activities were thoroughly planned, it was essential to attend to the evolution of the students' production class by class to define the next instructions. The incorporation of the sheets (described in the methodological proposal section above) was substantial to achieve a better ordering of the elaborations and their corresponding presentation. This way a precise description of the recipes, samples and settings was achieved.

In stage 1, the students mixed materials intuitively and the teaching team progressively guided them to reach a final material, but without establishing limitations or strict requirements. The request was that they generate the material in the way that was best for them and that offered versatility taking into account the next stage of application to a product.

In stage 2, the students had to design a product that was adapted to the properties and possibilities of the material they created. The typology of the product to be designed was of free choice, defined by each student in relation to the properties detected in the biomaterial achieved in the previous stage. The objectual results were diverse, in most cases the relationship of relevance between the material and the product was positively observed.

2020: First year in the pandemic

The modality and distribution of the classes was modified during the pandemic, becoming virtual meetings two days a week, of two hours each. Despite the change in modality, the collaborative workshop proposal was maintained to develop the exercise. In order to reduce the uncertainty and dispersion involved in any exploration, it was decided to focus the exercise on the design of a specific product: a desk lamp. Thus, a series of specific requirements were determined: the loads of the biomaterial were limited to food disposal, and the function of the product, its dimensional range and its relationship with other elements of the environment were defined. No less important is that in order to monitor the work from within the virtuality, it was necessary to incorporate virtual platforms, such as Miro, Mural, Padlet, in addition to the tools provided by Google (Classroom, Drive, YouTube), which the Chair used during the pandemic.

Although the virtual experience generated many doubts in relation to the proper development of the practical work, it was possible to verify the fulfillment of the goals set for learning during this practical exercise. The situation also highlighted the need to develop in the teaching team the ability to find alternative paths for teaching. Paths that many times proved better than those originally planned. A good example of this are the virtual tools that allow monitoring as a more orderly process and, also, allow presentation formats that are more in line with the environmental care (since it is not necessary to print hundreds of sheets) that the very same exercise tries to reflect.

2021: Second year in the pandemic

The modality and distribution of the previous year's classes continued with virtual meetings of two days a week, two hours per class. The criteria and dynamics adopted in the previous year were maintained. This made it possible to investigate, and even delve into, other content. The application of the biomaterial to the design of a product was addressed under the guideline: eating standing up. Thus, the students had to design a product to be defined in each case, analyzing a possible gastronomic experience. The use of the Miro platform was perfected as a fundamental monitoring tool for teachers, also functioning as a collaborative support for consultation in which all students could access the developments of their classmates.

The 2021 experience was characterized by replicating and perfecting the exercise planning from previous years, generating improvements in the results of the practical work. The students elaborated deeper analysis around the possibilities of their biomaterials, deeply understanding their properties and applying them to objects that were better suited to the workshop's setpoint.

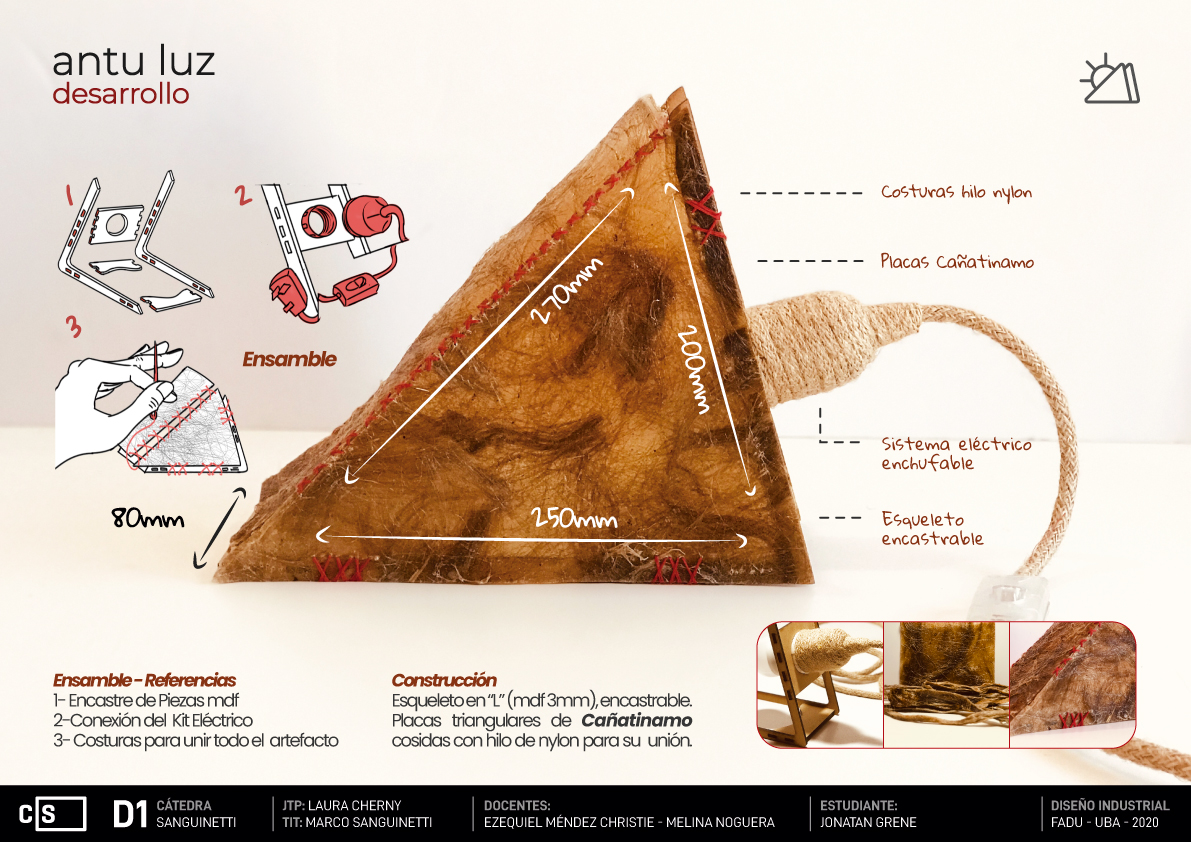

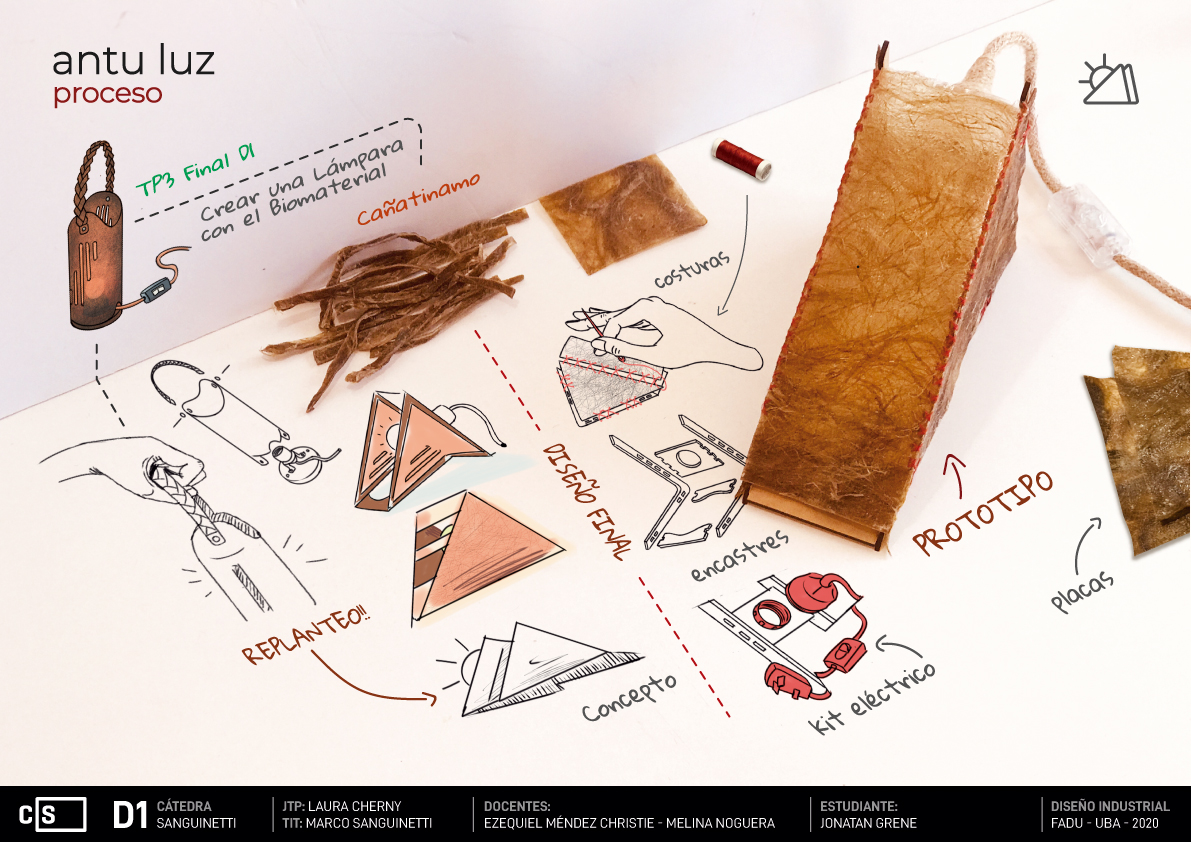

Below are some final presentation slides from the 2020 cycle exercise (Figure 6).

Figure 6: final presentation slides for stage 2 (student: Sophya Ramírez, Industrial Design Workshop 1, Sanguinetti Chair, FADU – UBA 2020).

CONCLUSIONS

The pilot experiences in the form of practical work within the Industrial Design Workshop at the Sanguinetti Chair of FADU-UBA during the 2019, 2020 and 2021 cycles have served to identify errors and successes of the methodology proposed by the biomaterials research team. The professors of the Chair, who largely are also members of the research team, exchanged and discussed reflections upon the experiences to arrive at certain conclusions. The students also provided their perspectives through surveys answered at the end of each academic year. The following paragraphs cover a synthesis of quite valuable observations, both for the reconsideration and for the strengthening of the proposals expressed in this project.

The enviromental subject

The environmental issue generates more and more adhesion among the new generations of students who enter the Industrial Design career and, consequently, a special commitment is perceived from behalf of the participants in the practical work of design with biomaterials. Somehow, by including this topic in an initial course of the career, students naturally acquire the design responsibility of investigating alternatives for the use of materials while avoiding damage to the environment.

As for the teaching team, the incorporation of this design approach has made it possible to question those decisions (little so during previous cycles) on the use of materials that we could call “traditional” in the different practical exercises developed in the Chair.

Territory resources

These experiences with biomaterials in the Industrial Design Workshop served to acknowledge the links that exist between environmental responsibility and social commitment in design projects. The need to get to know the resources that each territory grants when designing was certainly an innovative attitude for many students who find themselves in the initial stages of the career. This identification and utilization of the available resources in the environment inhabited by each student constitutes a true democratization of the apprenticeship.

In the different projects the students developed, there are certain recurrences in the choice of the components for the biomaterials. This is undoubtedly due to the fact that they work with household discards and their availability is determined by local consumption habits. It is possible to imagine that this approach, already characteristic in this practical exercise, could also be transferred to other experiences within the career at the University of Buenos Aires and thus provide an alternative for the treatment of local urban waste.

The exploratory sense an the lessons learned

Since the students participate in the entire process, from the "cooking" of the material to the application of it to a product, they become true experts in the generation of a new material of their authorship. Making them participate in the process in an integral way allows them to build an approach almost of a scientific nature, structured on the hypothesis-verification sequence. So that in the stage of applying the biomaterial to a product (to be designed by themselves) they are based on performance predictions of the material, something that is empirically verified in the last classes.

Although the Chair carefully outlines the exercise, it is actually an exploration that is typical of the workshop dynamics. The practical exercises in the workshop promote the appearance of the unforeseen, that which is not planned, thus generating a collective construction that provides novelties, which are later included almost spontaneously in the planning of the next exercise, or even in the one that is being carried out. A good example of this is what the Chair has decided to call lessons learned and anecdotal accounts. The lessons learned invite to consider the “mistake” and transform it into data from which we can learn. That which is believed did not go well can be interpreted as new and valuable information. The anecdotal accounts seek, through humor (with photos, memes or short stories) to socialize the eventualities that each student went through in this experience in their environment (often the family home) and, at the same time, retain useful information for learning.

In the experiences carried out in the design workshop, it has been detected that working with biomaterials allows students to obtain empirical learning. Through guided exercises, the teaching team accompanies each student in training their observation and reflection skills. The guides and templates prepared by the Chair for the fulfillment of the requested tasks have facilitated the standardization of the results in order to obtain results that can be compared during the evaluation instances.

In pandemic

During the 2020 and 2021 cycles, developed remotely due to the COVID-19 pandemic, there were certain alterations in the planning of the exercise in relation to the experience carried out in the 2019 cycle under the traditional face-to-face class modality. Although the group of students worked in a similar way in the exploration and creation of the material, the monitoring and presentation of the biomaterial tests carried out was strongly modified. The faculty had to settle for almost exclusively visual appreciation in addition to relying on the stories related by the students, who thus tried with great effort to reproduce the sensory experiences involved in the exploratory projects. This new challenge imposed by the virtual class modality led to the necessary incorporation of new tools to optimize the exchange between students and teachers. New models of record sheets were then developed for the registration and presentation of samples, numerous theoretical lectures were offered with external specialists, work was carried out on platforms for collaborative online design and the audiovisual format was incorporated in instances of partial and final deliveries.

Many students at the University of Buenos Aires come from cities and towns in the interior of Argentina, and some as well from neighboring countries. During these pandemic cycles, the vast majority of them chose to return to their places of origin to live with their families, taking advantage of the distance learning modality. This circumstance led to the detection of material opportunities available in each of these places. The Chair’s teaching team, then, insisted on the use of local materials to carry out the exercise. As a consequence of this setpoint, the students not only acquired a certain awareness of the environmental implications of design, but also understood the importance of the commitment that, as designers, they must assume with local resources, both from a material and cultural perspective.

As it happens in every Industrial Design project (and therefore also when designing biomaterials) the experiences crossed by the designers constitute a true enlightenment and update on their own culture and that of the people involved. Perhaps, that is where the highest purpose of the proposals described in these pages resides: to produce, through learning, an encounter with the disciplinary identity of both students and teachers.